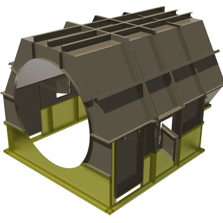

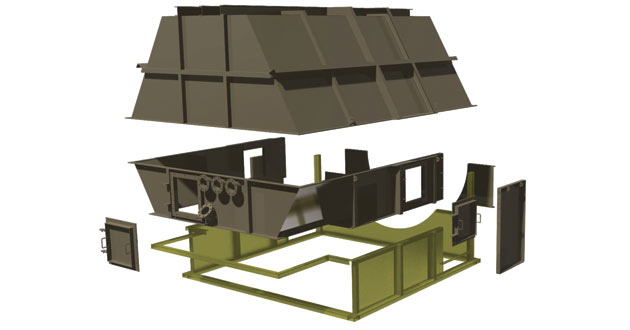

SAG Mill Cover

BHP Billiton Cannington Mine, located in North West Queensland is a significant miner and exporter of Silver and Lead concentrate via the Port of Townsville.

Orana Engineering was engaged by Cannington site maintenance to provide workshop fabrication drawings for a replacement cover to address the issue of corrosion that was present around flanges and access openings on the existing Sag Mill Trommel Sump Cover.

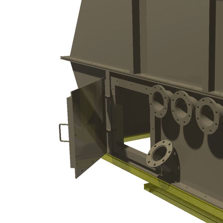

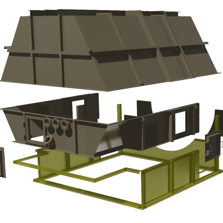

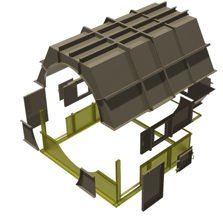

Over time corrosion build up through these areas had made required maintenance access impractical and normal operations were deemed to have become unsafe. It was initially suggested that local repairs be made to individual areas however the final decision was made that the two upper sections (i.e. the middle and top sections) of the existing cover were to be removed and replaced by two new sections incorporating more efficient and corrosion resistant access, as designed by Orana Engineering.

An initial site visit was undertaken by Orana Engineering design staff to obtain site measurements, photographs & relevant existing drawings to aid in the design process, as well as identifying what existing documentation & drawings would require revision to ensure continuity for future works.

After obtaining this information the Orana Engineering design drafting team were able to create a detailed 3D model of the existing structure incorporating the new components to produce a full set of detailed shop fabrication drawings as well as revising multiple existing drawings. All of this design work was completed and issued to the client in just over a week, only possible due to the excellent work by the engineering and design teams and Orana Engineering’s rigorous quality assurance process. Shortly thereafter these drawings were reissued for construction after receiving client approval.

Orana Engineering was able to deliver an efficient and cost effective solution that was able to be implemented in the tight shutdown timeframe that the client had available. The new cover sections and access panels have improved not only the safety of the trommel operation but also increased efficiency by reducing the time needed to perform maintenance and inspections.

If you would like any more information or details about Orana Engineering design drafting or engineering services, please do not hesitate to contact us or review our capabilities.