Engineering for Oil & Gas Operations

The Oil and Gas sector in Queensland has experienced rapid growth over past years with a number of basins throughout the region currently producing, or with the potential to produce oil and gas. The Gas sector in particular is an area that benefits from the mechanical, electrical, structural and control systems engineering services that Orana Engineering can provide. We are experienced working with clients in the Surat and Bowen Basins, and are strategically placed to support future expansion into the Galilee Basin.

From the upstream operations of extracting, processing and compressing Coal Seam Gas (CSG) to the downstream process of converting the gas into Liquid Natural Gas (LNG) for shipment and export, our engineering services, which include design, project management, design drafting, revisions and drawing management, are intended to support the ancillary services of the oil and gas industry including fixed plant and infrastructure such as water treatment plants, compressors and power stations. Orana Engineering can also provide support for the ancillary services associated with Underground Coal Gasification (UCG) operations.

It is important that any contractor or supplier to the oil and gas industry is familiar with acts and legislation that govern the operations onsite, and Orana Engineering ensures that staff are conversant with these. For further information on the legislation, please follow the links below.

Petroleum and Gas (Production and Safety) Act 2004

Petroleum and Gas (General Provisions) Regulation 2017

Petroleum and Gas (Safety) Regulation 2018

Explore the case studies below to learn more about the value we can add for our oil and gas clients.

Orana Engineering Oil and Gas Engineering

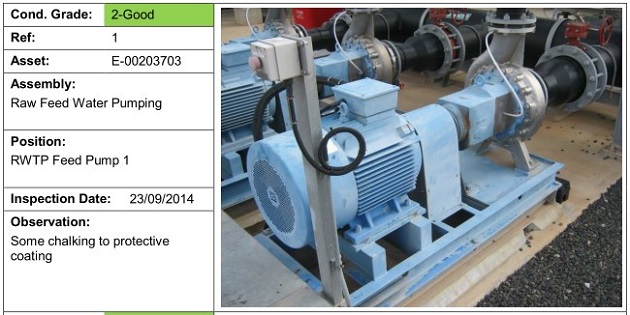

Plant Condition Assessment

Orana Engineering was requested by Veolia Water to perform a condition assessment of assets at the Kenya Water Treatment Facility which covered civil, structural, mechanical and electrical assets. Inspections were completed over a period of 6 days with Orana Engineering personnel of various disciplines working with site representatives across all areas of relocatable plant infrastructure. Observations were recorded and photographed enabling a detailed register and report to be produced. Orana Engineering updated the plant asset register to assist with ongoing management and ensure observations were in a format practical for plant operators. The final report grouped items within categories to assist in prioritising actions and was used by the client to create an action plan for rectification of faults.

Read moreBuilding Certification

Monadelphous Group was contracted to deliver the Talinga Pipeline Compression Facility for Origin Energy’s APLNG project. Towards the end of plant construction, the Monadelphous team engaged Orana Engineering to complete structural inspections and provide Form 16 Building Certificates for structures ranging from small plant air shelters to entire compressor train buildings and associated platforms. The inspections assessed construction to the requirements of AS4100: Steel Structures and AS1657: Fixed Platforms, Walkways, Stairways & Ladders - Design, Construction & Installation. The work was completed within strict timeframes by employees from Orana Engineering’s Chinchilla Office, situated in close proximity to the site. This allowed multiple site visits to be conducted at very short notice and with minimal travel and mobilisation costs.

Read moreCombabula Bore Pump

Prime Pump Company was contracted by Origin Energy and Laing O’Rourke to supply an upgraded bore pumping system at Origin’s Combabula site. RIE Services was contracted by Prime Pump Company to supply and install electrical components for the upgrade, with Orana Engineering subsequently engaged by RIE Services to complete a fault protection study on the new installation. Using SKM Power Tools for Windows software and manual calculation techniques for verification, together with information from RIE and Prime Pump Company, Orana Engineering produced an HV/LV model calculating fault levels and completing a protection co-ordination study. From the study it was recommended a new circuit breaker be introduced to protect the transformer, variable speed drive and supply cables.

Read moreAPA Group Tender

APA Group released a project for tender comprising electrical and instrumentation for rectification of hazardous area compliance issues. Condamine Electric Company (CEC) tendered on the work and engaged Orana Engineering to prepare a detailed estimate of costs to complete the rectification works. Orana Engineering undertook a detailed review of the scope and drawings in the tender package to ascertain requirements. Quotes for non-standard equipment were obtained and a detailed cost estimate was created. Additionally, from the scope review Orana Engineering identified and compiled a comprehensive list of questions which were subsequently raised by CEC during a tender site visit. Upon provision of responses, Orana Engineering delivered a complete capital estimate to CEC for tendering.

Read moreQGC AIWT Design Review

Hutchinson Builders Toowoomba was contracted to deliver portions of the Water Aquifer Injection Trial at QGC’s Woleebee Creek site. Prior to construction, Hutchinson Builders engaged Orana Engineering to perform a design review of all mechanical technical documentation associated with the Pond Transfer Pump Station. The review aimed to determine whether sufficient detailed information had been provided to allow Hutchinson Builders to successfully complete construction. Orana Engineering completed and issued a design review report which detailed recommendations from the review. During construction, Hutchinson Builders also engaged Orana Engineering to perform an inspection of a buried HDPE pipeline and to assess the construction of the pipeline against requirements of engineering drawings and specifications.

Read more