At Orana Engineering people are without question the most important asset of business. To deliver the services and projects that the company provides, it is essential that Orana Engineering employees have the skills and personal qualities that are suited to the business model and business philosophy of the company. For this reason, not everyone is cut out to work for Orana Engineering.

To be suitable for a position at Orana Engineering, you must:

- Be task orientated, focused on completing a job, not watching the clock;

- Value feedback as a learning opportunity, one that can lead to personal improvement;

- Be accountable and responsible – don’t pass the buck;

- Enjoy communicating and value the importance of it;

- Value the respect and friendship of your fellow employees;

- Have excellent attention to detail and value that such is essential to Orana Engineering’s business; and

- Care about the quality of services that Orana Engineering delivers and value the reputation of the business.

If you have these qualities we want to hear from you, so please either submit an application for one of our current vacancies that is applicable to your skills or if there are none suitable, please submit an application anyway.

As an employee of Orana Engineering you will be eligible to participate in the social program and you will be encouraged to continually develop yourself via training and professional memberships.

You could be working on projects like -

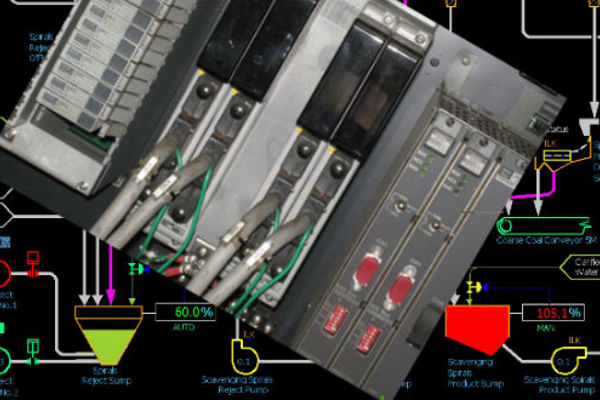

Yokogawa DCS Upgrade

Since 2005, Orana Engineering has provided 24/7 support for Oaky Creek Coal control systems. At the coal handling and preparation plant, a Yokogawa DCS installed in 1998, is used as the primary control system.

With existing CentumCS Unix software no longer supported by Yokogawa, it was essential to complete an ...

Crusher Circuit Upgrade

Eloise Copper Mine purchased a Metso dual deck vibrating screen to replace an existing smaller screen and a second Omnicone cone crusher to provide a secondary crushing circuit for increased production and efficiency. Orana Engineering was engaged to develop a design solution and detailed drawings for the secondary crushing circuit ...

Conveyor Upgrade Project

Carborough Downs Coal underground mine had transitioned from a bord and pillar mining system to longwall. The result was a need to upgrade capacity of the coal clearance conveyor system. Orana Engineering was engaged to provide Client Engineering assistance to deliver underground conveyor equipment to meet the longwall production schedule. ...