Drawing Revisions

Over the life of an operation, many of a site's drawings will require revision which can be due to plant modifications or simply a drawing being updated with as-built information. Maintaining up to date drawing revisions reflecting this information is integral to a site providing a safe, practical and efficient workplace.

When a client makes changes during the design, construction and installation phases of a project (e.g. producing as-built plans), or when modifications are made to existing plant a drawing revision is required. Clients provide red pen or hand drawn mark-ups which our experienced design draftspeople interpret and document, resulting in accurate electronic drawing revisions. Clients receive a well presented and accurate reflection of their mark-ups in PDF and CAD format (or other native format as required). The revision of drawings is about keeping drawing records up to date to accurately show the details of a plant's existing construction or to define the scope of what is to be installed or modified for a project. In turn this enables accurate information for all to access, with the potential to prevent safety hazards or delays associated with misinformation.

Continually managing drawing revisions can create cost savings and time efficiencies, which are often realised during the life of the operation (maintenance and operations) or the next project, when accurate records allow all parties to start with the right information and same understandings. Maintaining accurate drawing revisions is also a legislative requirement for some industries, particularly the coal industry or when dealing with electrical drawings.

Maintaining accurate drawing revisions

- Protects the safety of those operating or modifying the plant in the future by ensuring they are working with the correct information, and preventing the risk of misinformation causing injury, particularly around electrical work;

- Keeps the end user in mind - allowing maintenance and operational personnel easy and confident access to the correct information, ensuring processes can run smoothly. It is easier for personnel to make onsite decisions when the correct information is available;

- Encourages all team members to have confidence in all site drawings, encouraging new revisions to be updated as required, perpetuating a culture of accuracy and safety within the team. If issues arise, staff can have confidence in the information available as they know drawing revisions are a priority within the team and can be relied upon; and

- Cost and time savings for future modifications, making the process easier by ensuring accurate drawings are available as a starting point for future plans and modifications. Incorporated with a good drawing management system, client’s personnel can be confident that they are working with the most current and up to date revision.

Outsourcing drawing revision services to Orana Engineering means that our clients do not have to dedicate time or resources to this service, including resourcing suitable discipline specific personnel or the overheads for maintaining software updates. Clients can have confidence that Orana Engineering will do it once and do it right, taking into consideration the effect that any revisions may have in the bigger picture, through our drawing management systems identifying any additional drawings that may also need to undergo revision. Our ability to call upon qualified and discipline specific personnel with trade backgrounds ensures accurate interpretation of client’s markups. Our staff understand that drawings are more than lines on paper, that they reflect something real onsite and have real implications for those relying on the drawings.

Our rigorous Quality Assurance systems ensure that drawings are efficiently revised with the highest level of accuracy. The thorough drawing revision service includes designing, checking, engineer calculations (where applicable), CAD drafting and back drafting checks, engineering design drafting, reviews and drawing registration. If required by our clients, our in-house engineering expertise also allows for clients to benefit from qualified engineering checks on their revisions.

Orana Engineering has the resources and capabilities to provide our clients with a complete engineering and design solution that is inclusive of performing engineering design drawing revisions, as-built revision and importantly maintaining the register of the sites drawing management system.

Contact Orana Engineering for further information about our drawing revision services and how they complement our drawing management systems and design drafting services. Or for more information about the services Orana Engineering can provide, please review our Capability Statement.

Orana Engineering Drawing Revisions

Village Kitchen Upgrade

The Village Kitchen at Glencore’s Hail Creek Mine camp was scheduled for upgrade with Orana Engineering engaged to provide engineering support for electrical, civil and building works, including a new shed. A site visit was conducted to determine the scope of the upgrade and to collect site information comprising photos, drawings, measurements and location of water and gas services.

From the information gathered, Orana Engineering provided engineering design and project management of the Village Kitchen upgrade including a new shed distribution board, concrete slab, layout and connection of services to the new shed and prepared a detailed scope of work document for tendering purposes.

Orana Engineering design drafters produced RPEQ certified GA and concrete drawings showing details of services to be relocated, a slab and loading dock drawing, a new single line diagram for the distribution board, and revisions to existing distribution board drawings.

Rajant Network

Glencore planned to install the CAT MineStar Terrain Office system at its Oaky Creek Coal Mine to support GPS positioning and live maps in CHPP stockpile dozers. As part of the upgrade, mine infrastructure and dozers required hardware installation to connect the dozers to the site network and enable communication with MineStar servers. In line with other Glencore sites, it was chosen to implement a Rajant wireless network to cover stockpiles and provide connectivity between dozers and the network.

Orana Engineering was engaged to provide electrical and Operational Technology (OT) engineering design, configuration and drafting support for the CAT MineStar GPS implementation including preparation of three new virtual servers for various applications. Orana Engineering electrical engineers developed a scope of work which provided an overview of the onsite electrical installation works required to be carried out by others with supply, installation, testing and commissioning project managed by an Orana Engineering electrical and control systems engineer.

Ash Water Return Pipeline Replacement

Ash slurry at CS Energy’s Kogan Creek Power Station is pumped to various locations around site via a pipeline originally installed for delivery of service water from the power station to the crusher area. With proposed pumping equipment capable of higher pressure output, a project was set up to review the engineering calculations and potential risks.

Orana Engineering was engaged to conduct concept design investigations considering options for repair or replacement of the pipeline. Outcomes from the review were provided to CS Energy summarising options considered and proposing the use of carbon steel (potentially lined for corrosion resistance) as the optimal replacement for fibreglass piping. Advantages and disadvantages of carbon steel were also presented such that the client was fully apprised of its properties.

As only limited drawings of the existing pipeline were available, Orana Engineering design drafters produced pipeline general arrangements for information.

Filter Press Installation

A filter press initially planned for Glencore’s Clermont Coal Mine was relocated for installation at Collinsville Coal Mine in a trial capacity to assist in reducing the amount of tailings produced from the wash plant.

Orana Engineering was engaged to provide engineering and drafting support for the filter press installation scope of work, to assess suitability of the Clermont detailed design for construction at Collinsville and to plan and implement arrangements for the installation.

Considerations to ensure a smooth installation at Collinsville included concrete design and a structural analysis. Calculations were also undertaken to determine design wind and earthquake loads for the site to Australian Standards AS/NZS1170.2 and AS1170.4.

Orana Engineering design drafters produced a new site plan showing set-out of the filter press slab with new and existing underground services detail incorporated, with RPEQ Supervision.

Chain Feeder Modifications

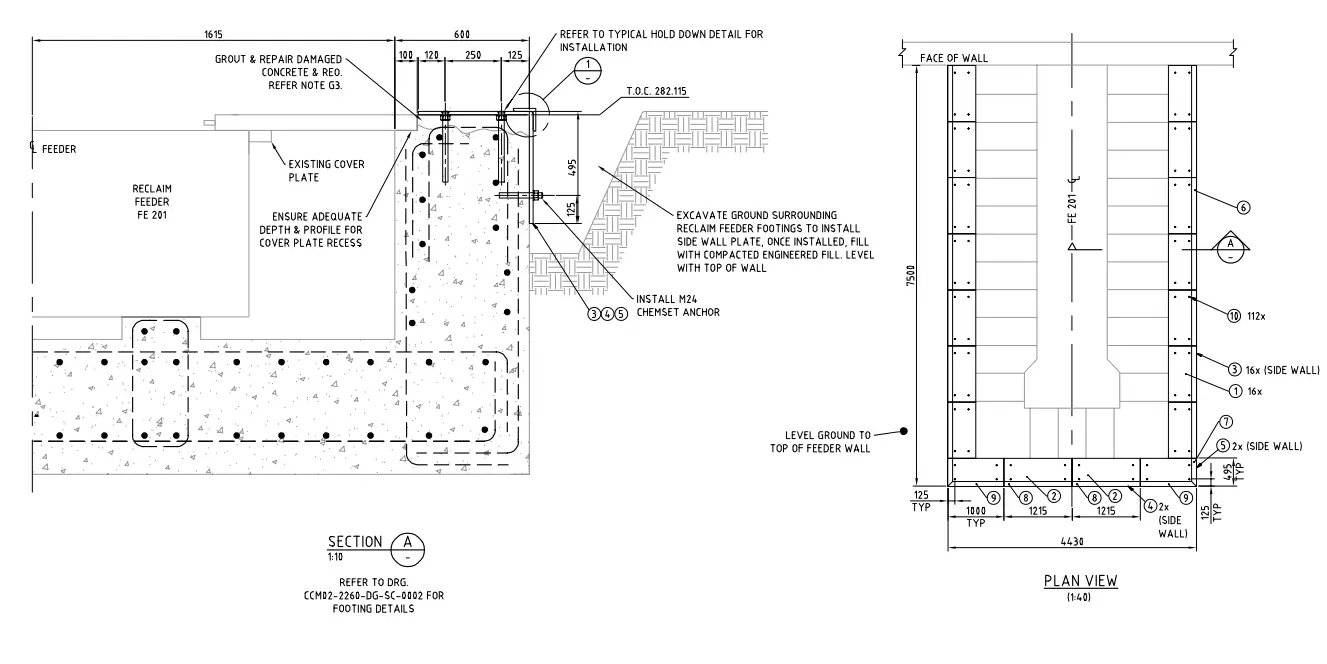

The CPP chain feeder at Glencore’s Clermont Coal Mine required repair and the assistance of Orana Engineering was sought with development of an appropriate methodology and associated detailed design drawings.

Steel plates had been installed to cover the chain feeding system, which over time had been degraded by the dozer feeding the system chipping away at concrete footings. This caused exposure of the steel plate edge which subsequently caught on the dozer bucket. The result was a build-up of material around the chain, causing downtime to reinstate plates and clean up material.

Orana Engineering’s basis of design was for repair of the existing reclaim feeder concrete and development of suitable protection to reduce future wear damage and deterioration from dozer contact. Existing concrete footing drawings were revised to reference new concrete and steel detail and then issued for client review prior to finalising, with RPEQ supervision.

.jpg)

Oily Water Pond

Origin Energy’s Talinga Gas Plant oily water system treats water created during the gas compression process. Effluent from the system is pumped into the water-gathering network, delivering water to the main water treatment plant.

Orana Engineering was engaged by Origin Energy to evaluate the oily water system and conducted a high level assessment of options to reduce the risk of uncontrolled release of contaminated water from the wetlands system that was controlled by interim means.

Outcomes were presented to the client summarising options to reduce or eliminate identified risks. Orana Engineering subsequently provided detailed mechanical and electrical design and drafting for the approved option.

Deliverables for the project included a basis of design document, detailed design and a revison of the Wetland Operations & Maintenance Manual.

Precipitator Controllers

Incitec Pivot contacted Orana Engineering for assistance in identifying options for upgrading its Mount Isa Acid Plant Electrostatic Mist Precipitators (EMP). This was primarily to mitigate issues with EMP 7 and 8 which were contributing to low dust capture efficiencies, converter catalyst degradation and potentially premature damage to tube bundles.

Orana Engineering electrical engineering personnel sourced additional information on issues experienced and liaised with equipment manufacturers for recommended solutions. A design review table was prepared to summarise and document data from previous reviews including reports, tests, inspections and previous recommendations.

Orana Engineering provided offsite assistance in co-ordinating procurement and installation with deliverables to the client comprising the finalised design review summary table, BOM, equipment quotes and redline drawing mark-ups for upgrade of the EMP controller.

.jpg)

HA Reclassification

Origin Energy’s Mount Stuart Power Station operated three power turbines driven by aviation kerosene and consideration was being given to converting these to operate on an alternative fuel source. Orana Engineering was engaged to conduct a hazardous area classification assessment covering re-classification of site areas relevant to the fuel conversion and to address handling of flammable gases produced as part of normal plant operation.

The objective was to establish whether an explosive atmosphere would exist around equipment following the proposed fuel conversion and to verify the classification and extent of hazardous areas in line with regulatory guidelines and standards AS 60079 Series and IE Model Code of Safe Practice, Part 15.

Upon conclusion of Orana Engineering’s assessment, the client was provided with a comprehensive Hazardous Area (HA) Classification Report confirming that ventilation at the plant was deemed adequate due to the outdoor location of most equipment and artificial ventilation within turbine and pump enclosures. Revised HA area classification drawings were also provided by Orana Engineering drafting personnel.

Brine Concentrator Drain Pump System

Orana Engineering was invited by MFE to provide an estimate for subcontract works for the Veolia Water brine concentrator drain pump system at Kenya Water Treatment Plant.

Brine concentrators at the plant periodically release high temperature and corrosive wastewater to floor sumps to control or monitor processes. The PVC pipework from floor sumps had become unserviceable due to the pipeline material not being rated for high temperatures. The existing drainage pipeline needed to be replaced with a durable system capable of withstanding high temperature corrosive wastewater.

Orana Engineering’s involvement in the project encompassed provision of engineering support (hydraulic, mechanical, civil and electrical design) and drafting support including revision of existing drawings and generation of new hydraulic, mechanical, civil and structural drawings with RPEQ supervision.

Main Sub Upgrades

The main substation at Glencore’s Oaky Creek Coal is essential for surface operations. Site personnel had highlighted multiple projects for implementation to collectively improve the integrity and reliability of the main sub. For each of the projects there were common elements and beneficial outcomes for executing them concurrently.

Given the critical nature of the projects and the importance of success, Orana Engineering developed a project management and design scope for provision of a dedicated Electrical / Control Systems Engineer from its Engineering Team.

Projects under the scope consisted of safety and reliability upgrades for OCC Main 66 / 11kV substation including automated racking of circuit breakers, interlocking of transformer tap changers and parallelling control, cable pit sump pump control.

Work undertaken included detailed design, PLC and DCS configuration, protection relay configuration, racking controllers, and commissioning whilst also mananging the client's drawing management system.