Engineering Audits & Inspections

Engineering audits and engineering inspections are an integral part of both new projects on site and ongoing operations. They are an exercise in benchmarking to assess and understand what is currently in place and quantifying this through reporting. They can identify areas where corrective actions may be required to achieve compliance, or where improvements would provide a benefit to the client. Engineering audits and engineering inspections are tools that can also be used to determine if a project was installed in accordance with the original designs, and provide an accurate starting point for future projects. They can also be an opportunity to have an independent set of eyes review the situation and provide an informed assessment.

Orana Engineering employs a risk based approach to help clients prioritise any corrective actions or recommendations. Engineering reports are produced confirming how existing systems and operations align against current standards or amendments to standards and identify any corrective actions that may be required to meet compliance.

Our audit and inspection services are relevant across all engineering disciplines including electrical, mechanical, structural and control systems. Explore the case studies below for more information on engineering audits and inspections services by Orana Engineering.

Orana Engineering Audits & Inspections

CHPP Structural Repairs

Glencore’s Newland Coal operation required removal of three Redispan conveyor modules at the tail end of its CV805 conveyor, leaving the head end modules in place. Assistance was sought from Orana Engineering in evaluating the stability and suitability of the head end support structure in withstanding the longitudinal loads of the conveyor.

Orana Engineering conducted a high level inspection and provided structural engineering advice as to the optimal lifting methodology to prevent overloading of the conveyor supports and pins as well as identification and recommendation of necessary limitations such as wind considerations and applicable exclusion areas. A review of the linkage of each remaining longitudinal brace was also undertaken to evaluate the stability of sections prior to their removal.

Upon conclusion, a letter of recommendation was presented to the client detailing outcomes of the Redispan structural review and installation, and providing engineering advice for the demolition works.

Light Poles Review

Orana Engineering was contacted by Glencore’s Oaky Creek Coal Mine to undertake a structural review of lighting towers situated at the Tieri township sporting oval. Existing tower bases had been buried for approximately 20 years and were displaying evidence of corrosion to anchor bolts and baseplates.

Orana Engineering conducted a review of client-supplied documentation and photographs and gathered additional information to determine repair requirements. Following the review, a letter of recommendation was provided to the client outlining repairs required for continued operation of the lighting towers, with RPEQ structural supervision.

Additional support was provided by Orana Engineering with a further review of lighting towers within the Tieri Aquatic Centre and Shopping Centre. In this instance Orana Engineering was also able to capture 3D data from light poles using its Faro 3D laser scanner. The client was presented with recommendations for tests or further analysis required.

Sampler PRT Documents

Process engineering personnel at Glencore’s Oaky Creek coal mine identified a need for review and gap analysis of existing coal sampler PRT (Production Resources / Tools) SAP documents, to determine where these differed from the recommendations of the original equipment manufacturers (OEMs) and from the PRTs of other Glencore sites.

The assistance of Orana Engineering was sought in conducting the review and documenting differences or gaps identified, for further discussion with site engineering contacts. Outcomes from the analysis were documented in the form of a Gap Analysis Register for client review.

With client approval, revised or additional PRT’s were developed by Orana Engineering as required to close all gaps, with changes then presented to the client to determine any final modifications to be made prior to handover.

.jpg)

HA Reclassification

Origin Energy’s Mount Stuart Power Station operated three power turbines driven by aviation kerosene and consideration was being given to converting these to operate on an alternative fuel source. Orana Engineering was engaged to conduct a hazardous area classification assessment covering re-classification of site areas relevant to the fuel conversion and to address handling of flammable gases produced as part of normal plant operation.

The objective was to establish whether an explosive atmosphere would exist around equipment following the proposed fuel conversion and to verify the classification and extent of hazardous areas in line with regulatory guidelines and standards AS 60079 Series and IE Model Code of Safe Practice, Part 15.

Upon conclusion of Orana Engineering’s assessment, the client was provided with a comprehensive Hazardous Area (HA) Classification Report confirming that ventilation at the plant was deemed adequate due to the outdoor location of most equipment and artificial ventilation within turbine and pump enclosures. Revised HA area classification drawings were also provided by Orana Engineering drafting personnel.

Orana 4 Pump Station

Veolia Water engaged Orana Engineering to look into options for a replacement pump station at its QGC Kenya Central Water Treatment Facility.

High level concept design investigations were initiated for options to replace the existing diesel driven manually controlled pump system for transferring brine from the site's Orana 4 Pond to the plant for treatment. Both a land based primed pump station and a water based floating pump station were given high level consideration. A detailed concept options report was developed for review and consideration by site stakeholders.

CHPP Projects - Water Balance

Orana Engineering was requested by the CHPP Manager Capital Projects at Glencore’s Collinsville coal mine to provide engineering and scoping assistance with respect to the mine’s underground water service repair and upgrade scope of work.

A member of the Orana Engineering mechanical engineering team attended site to liaise with onsite stakeholders, operators, plumbers and surveyors and to gather information on raw water and potable / fire water supply issues being experienced.

Upon return from site, a high-level engineering review was conducted along with detailing of raw water and potable / fire water scopes. Basic hydraulic modelling was also carried out to identify pressure spike issues and water hammer. Following review completion, the client was provided with a basis of design and a summary of Orana Engineering’s findings and recommendations.

CHPP Monorail Assessment

Glencore Coal Collinsville sought assistance from Orana Engineering in assessing multiple monorail designs within the CHPP area. The design review was to determine compliance with Australian Standards, including analysis of the structural capacity of each monorail, taking details from design drawings, 3D scans of the plant and physical measurements.

Fifteen monorails in total were assessed via visual and non-invasive means to determine their general state. Photos were cross-referenced with 3D scan data of the plant and existing structural drawings, with a structural assessment completed on all monorails to AS1418.18 using SpaceGASS and spreadsheet calculations.

Deliverables to the client upon conclusion of the study included a summary of design review results and recommendations for remedial action. Results from the assessment allowed updated certified as-built drawings of each monorail to be produced.

Compressed Air Upgrade

Anglo American’s Moranbah North CHPP operations personnel contacted Orana Engineering to investigate problems with low compressed air pressures and air flow rates. There were additional concerns regarding compressor reliability associated with the operation of equipment, valves, tooling, maintenance and instrumentation.

Orana Engineering conducted an onsite investigation which included preparing as-built drawings of the high-level compressed air distribution network within the CHPP. A review of historic transmitter data for the system was also carried out to identify issues and bottlenecks. System performance was also reviewed against site-checked pressures and engineering flow rate and pressure loss.

Upon conclusion of the investigation a summary of findings and recommendations was presented to the client encompassing as-built drawings, calculations, a summary of works and recommendations for resolution.

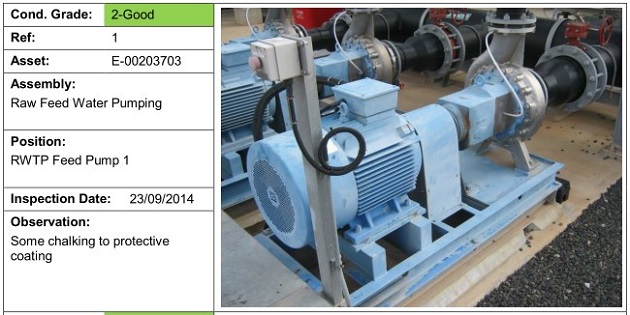

Structural Audits

Navarre Minerals engaged Orana Engineering to perform a structural audit of major assets within the processing plant at its Mount Carlton Gold Mine. The audit was limited to non-invasive, visual inspections of major assets and targeted obvious structural issues which would normally be identified as part of a condition inspection.

A desktop risk assessment was performed by Orana Engineering with documented results including a photo of each fault, relevant equipment details and location, observations, perceived fault severity and recommended remedial actions.

Findings from the audit were presented to Navarre within four categories ranging from ‘Monitor’ to ‘Minor’, ‘Major’ and ‘Severe’ with recommendations for follow-up via an onsite risk assessment and remedial actions as appropriate.

Crusher Gearbox

At the request of Glencore’s Collinsville Open Cut Coal Mine, Orana Engineering personnel attended site to perform a visual inspection on the CCR106 Abon Crusher following failure of the gearbox-to-crusher mounting studs.

The focus of the inspection was assessment of damage to impacted structural steel members on the crusher floor which had resulted from gearbox movement during the failure, and to troubleshoot the reason for the stud failure.

A summary of observations and supporting photos gathered during the inspection was compiled for presentation to the client. In addition, Orana Engineering provided a professional opinion regarding possible scenarios leading to failure of the mounting studs and offered recommendations for additional checks on the integrity of the crusher infrastructure.

LOM Pit Air Audit

Deficiencies with existing and Life of Mine (LOM) pit compressed air systems at Xstrata Coal’s Oaky No.1 Underground Coal Mine had been resulting in numerous production delays. Orana Engineering was engaged to investigate, analyse and provide delivery strategies for ensuring acceptable air pressures and flow rates were achieved for remaining mining activities within the site LOM Plan.

Considerations for improvement included additional compressors and piping system changes where required to achieve improved compressed air flow.

Orana Engineering conducted analysis using isothermal flow equations with a selection of these then verified via hydraulic modelling. Conclusions from modelling identified maximum allowable pipe lengths and flow rates for optimal compressed air flow, with subsequent improvement recommendations provided to the client.

Gravity Take-Up Access Platform Audit

Orana Engineering undertook an audit of ladders, steps and walkways associated with the Collinsville Open Cut CHPP gravity take-up (GTU) access platforms. A desktop audit was completed from photos and technical information gathered on site and with reference to AS1657 "Fixed Platforms, Walkways, Stairways & Ladders - Design, Construction & Installation" and the client's own standard for ladders, steps and elevated walkways.

At the conclusion of the audit, a letter of recommendation was provided to Collinsville Open Cut, documenting audit findings, cross referencing photos and detailing remedial action necessary for compliance. Signage requirements were also determined within the scope of the audit and included in audit recommendations.

Underground Structural Audit

Orana Engineering was engaged by Glencore's Ernest Henry Copper Mine to complete a preliminary inspection and condition assessment according to AS13822 "Basis for Design of Structures - Assessment of Existing Structures". Outcomes from the audit were presented with a focus on facilitating optimal rectification and categorised in level of significance from high end catastrophic, through critical, high and medium, down to those items of low significance.

Orana Engineering added additional value to the client by identifying various non-conformances of access systems, general industry standards and safeguarding.

Plant Condition Assessment

Orana Engineering was requested by Veolia Water to perform a condition assessment of assets at the Kenya Water Treatment Facility which covered civil, structural, mechanical and electrical assets.

Inspections were completed over a period of 6 days with Orana Engineering personnel of various disciplines working with site representatives across all areas of relocatable plant infrastructure. Observations were recorded and photographed enabling a detailed register and report to be produced.

Orana Engineering updated the plant asset register to assist with ongoing management and to ensure observations were in a format practical for plant operators. The final report grouped items within categories to assist in prioritising actions and was used by the client to create an action plan for rectification of faults.

QGC AIWT Design Review

Hutchinson Builders Toowoomba was contracted to deliver portions of the Water Aquifer Injection Trial at QGC’s Woleebee Creek site. Prior to construction, Hutchinson Builders engaged Orana Engineering to perform a design review of all mechanical technical documentation associated with the Pond Transfer Pump Station.

The review aimed to determine whether sufficient detailed information had been provided to allow Hutchinson Builders to successfully complete construction. Orana Engineering completed and issued a design review report which detailed recommendations from the review.

During construction, Hutchinson Builders also engaged Orana Engineering to perform an inspection of a buried HDPE pipeline and to assess the construction of the pipeline against requirements of engineering drawings and specifications.

CHPP Conveyor Capacity Audit

Vale at Carborough Downs Coal Mine required quantifying of current and possible future capacities of product conveyors at their coal processing plant in Central Queensland and high level recommendations to achieve increased plant tonnages.

Orana Engineering completed an initial site visit to gather the necessary information for a review of each of the conveyors. Engineering checks were completed to identify bottle-necks in the conveyor design such as motor power, drive equipment, belt curves, GTU mass, belt speed, belt capacity, belt tensions and electrical supply.

Orana Engineering issued a detailed report at completion of the study and provided concept level equipment modification recommendations for tonnage ranges advised by Carborough Downs Coal Mine.

Fire System Audit

BMA Gregory Crinum engaged Orana Engineering to perform an audit and inspection of the Crinum underground mine surface fire water system with respect to providing adequate pressure and flow for the Crinum North conveyor system and stockpile conveyor.

Orana Engineering completed a site inspection and audit against the design drawings, with site-verified information then used for compliance assessment in line with Australian Standards. The audit included in-depth assessment of the fire water system to Australian, BMA and site Fire Management Standards. Hydraulic modelling of the fire system was also undertaken to validate existing pressure measurements.

Orana Engineering was able to make recommendations regarding compliance and system hydraulic performance, which assisted BMA in improving system capacity.

MIA Services Audit

Orana Engineering was requested to complete an audit of water and wastewater services at BMA’s Blackwater Mine. The audit was to determine whether new go-line infrastructure would adversely impact the existing mine industrial area services, and whether additional infrastructure or upgrades were required.

Data collected from site by Orana Engineering was used to prepare a hydraulic model for each service. Modelling results, findings and recommendations were included in a detailed report outlining the capacity and utilisation of existing services to quantify available system capacity for the proposed new buildings. Additionally, Orana Engineering’s drawing revision services were utilised to formally revise site P&IDs to As Built, incorporating mark-ups made during the site visit.