Mechanical Engineering Consultants

Mechanical engineering is the use of energy to create motion while considering environmental influences, material properties and dynamic effects on and between bodies that are in motion. An in-depth understanding of how things move, behave or interact is required so that these properties can be accommodated within any good mechanical engineering design.

Mechanical engineering requires an understanding of core concepts including mechanics, motion, thermodynamics, materials science, structures and energy. Using this broad knowledge base, our mechanical engineers are able to analyze the properties and constraints and pull together the different elements required to create solutions and designs that suit operational requirements or resolve problems for our clients.

Orana Engineering has the capabilities and resources to provide mechanical engineering services including:

- Pumping systems (water or slurry) modelling and design – from simple single pump applications through to complex mine dewatering networks;

- Pressure piping design;

- Mechanical standards development;

- Mechanical systems and structure design;

- Machine guarding audits and design;

- Reagent distribution system design;

- Conveyor audits;

- Conveyor configuration and design; and

- Materials handling solutions.

We provide specialist mechanical engineering services to coal, metalliferous, oil and gas clients as well as industrial and commercial clients. Explore the case studies below for more information on mechanical engineering services by Orana Engineering.

Orana Engineering Mechanical Engineering

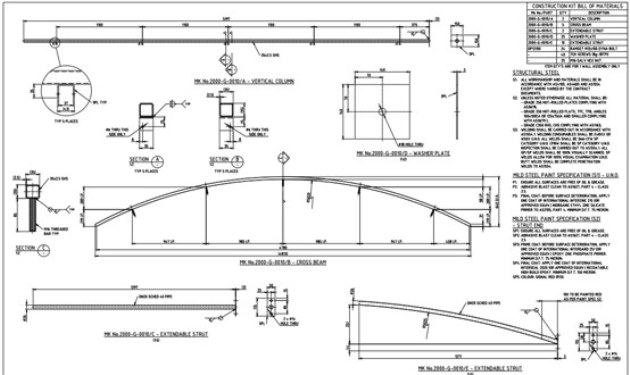

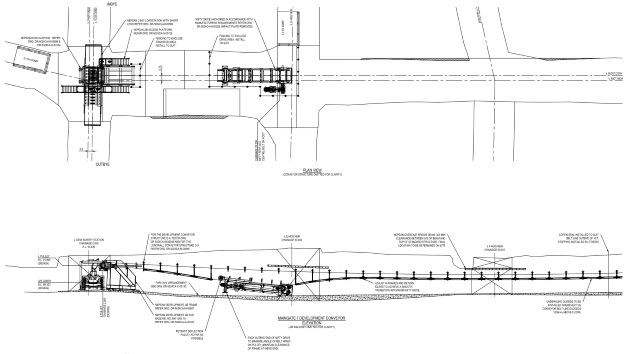

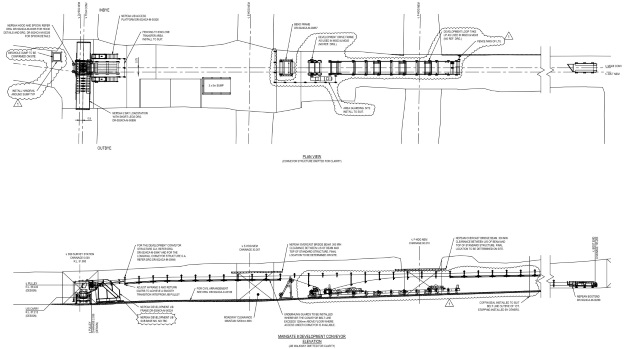

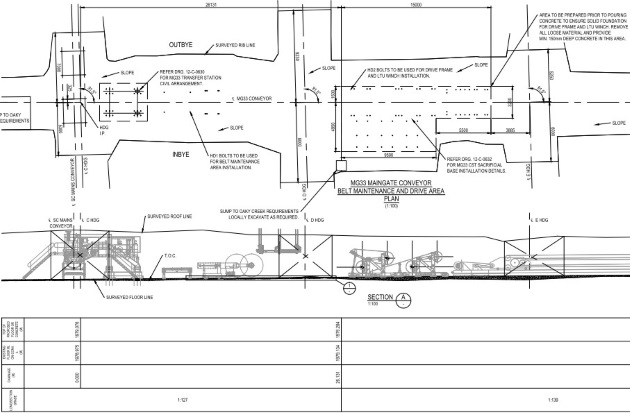

UG Conveyor Installations - MG Mechanical Installation

Detailing the installation of mechanical equipment and conveyor structures is one of the final steps for completing a maingate drive-head design. Installations designed by Orana Engineering for Glencore’s Oaky No.1 underground coal mine included detailing drive arrangements, transfer stations, take-up units, maintenance equipment and the overhead structures supporting the carry belt.

Mechanical design must consider a number of factors, including meeting the required operating capabilities, allowing for unimpeded access along travel roads and maintaining minimum belt curves. Often equipment is relocated from previous installations with minor modifications in transfer angle and number of drives. Orana Engineering has developed unique methods for completing this type of design, enabling us to keep total costs down for our clients.

Crib Hut Wind Load Review

Orana Engineering was contacted by Glencore for assistance in determining ground anchoring of three mobile crib huts at its Rolleston Coal Mine. The objective of Orana Engineering’s investigation was confirmation of applicable regional wind loads on each structure and requirements for external hold-downs with respect to sliding and overturning forces.

To assess anchoring options, calculation and analysis of wind forces on the mobile crib huts was performed using AS/NZS1170.2 for loading with various earth anchor types evaluated while also taking into consideration soil properties and ground compaction.

Based on structural engineering principles and calculations, and in consideration of Australian Standards and industry best practice, it was determined that all the mobile crib hut structures required anchoring to prevent sliding or overturning. Recommendations for the most appropriate type of ground anchor, along with general stipulations for application and installation of the these, was documented and presented to the client upon conclusion of Orana Engineering’s evaluation.

CHPP Structural Repairs

Glencore’s Newland Coal operation required removal of three Redispan conveyor modules at the tail end of its CV805 conveyor, leaving the head end modules in place. Assistance was sought from Orana Engineering in evaluating the stability and suitability of the head end support structure in withstanding the longitudinal loads of the conveyor.

Orana Engineering conducted a high level inspection and provided structural engineering advice as to the optimal lifting methodology to prevent overloading of the conveyor supports and pins as well as identification and recommendation of necessary limitations such as wind considerations and applicable exclusion areas. A review of the linkage of each remaining longitudinal brace was also undertaken to evaluate the stability of sections prior to their removal.

Upon conclusion, a letter of recommendation was presented to the client detailing outcomes of the Redispan structural review and installation, and providing engineering advice for the demolition works.

Ash Water Return Pipeline Replacement

Ash slurry at CS Energy’s Kogan Creek Power Station is pumped to various locations around site via a pipeline originally installed for delivery of service water from the power station to the crusher area. With proposed pumping equipment capable of higher pressure output, a project was set up to review the engineering calculations and potential risks.

Orana Engineering was engaged to conduct concept design investigations considering options for repair or replacement of the pipeline. Outcomes from the review were provided to CS Energy summarising options considered and proposing the use of carbon steel (potentially lined for corrosion resistance) as the optimal replacement for fibreglass piping. Advantages and disadvantages of carbon steel were also presented such that the client was fully apprised of its properties.

As only limited drawings of the existing pipeline were available, Orana Engineering design drafters produced pipeline general arrangements for information.

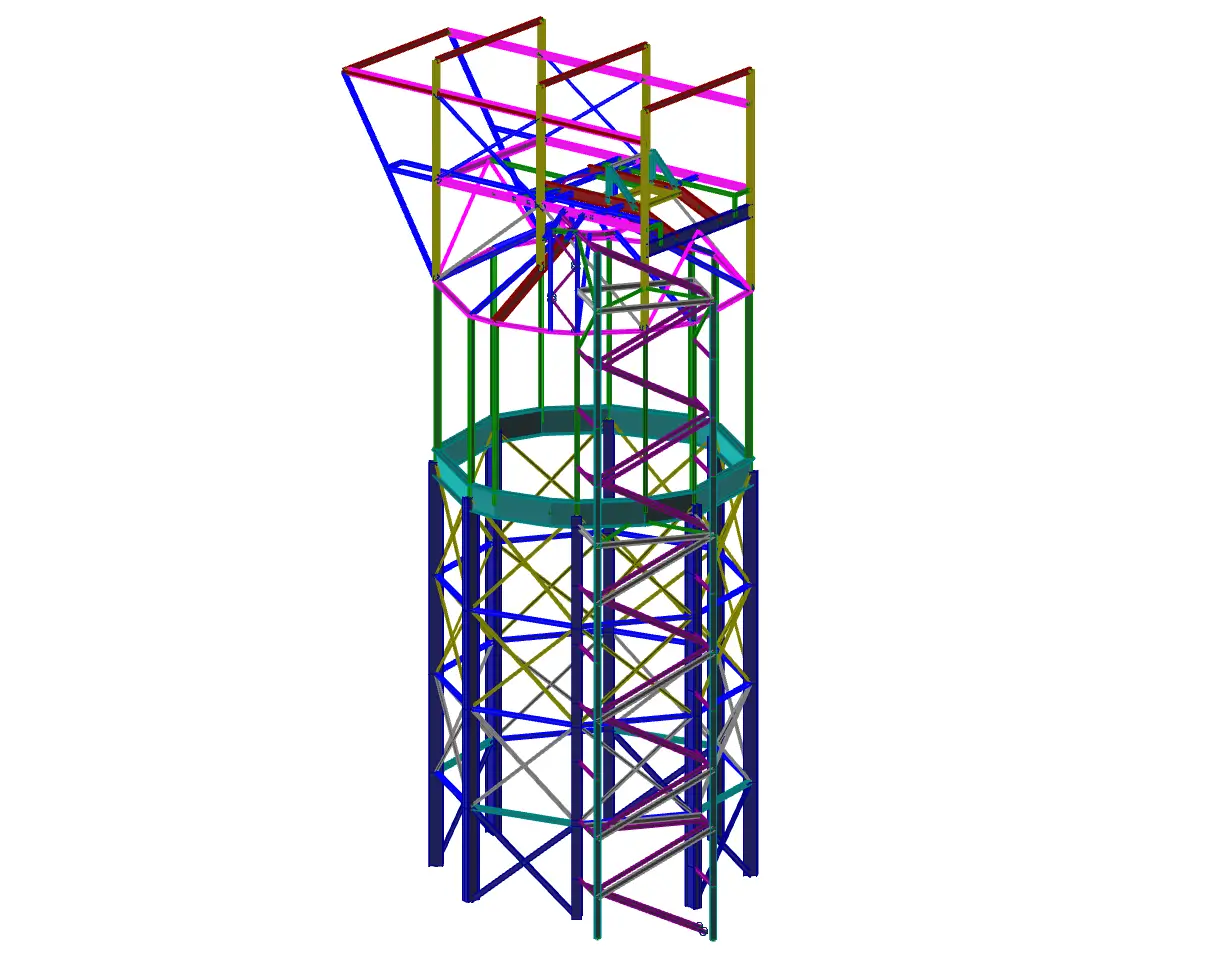

TLO Bin Support Repairs

Orana Engineering assisted Glencore's Clermont Coal with an engineering review of the structural integrity of head end support stools connected to its train load-out (TLO) bin ring beam as material build-up at the top of the bin cone had resulted in corrosion of several lower stools connected to the ring beam. Orana Engineering presented recommendations for temporary stiffening solutions and a repair methodology to restore conveyor supports to original design capacity.

Following the initial review, Clermont Coal requested that Orana Engineering undertake a further structural review of the TLO bin to analyse the effect of scaffold arrangements to be constructed on the bin and to confirm overall structural integrity with the additional applied loads.

Orana Engineering design drafters developed a concept design 3D model of proposed bracing including finite element analysis (FEA), and RPEQ certified detailed drawings for TLO column repairs were also delivered to the client.

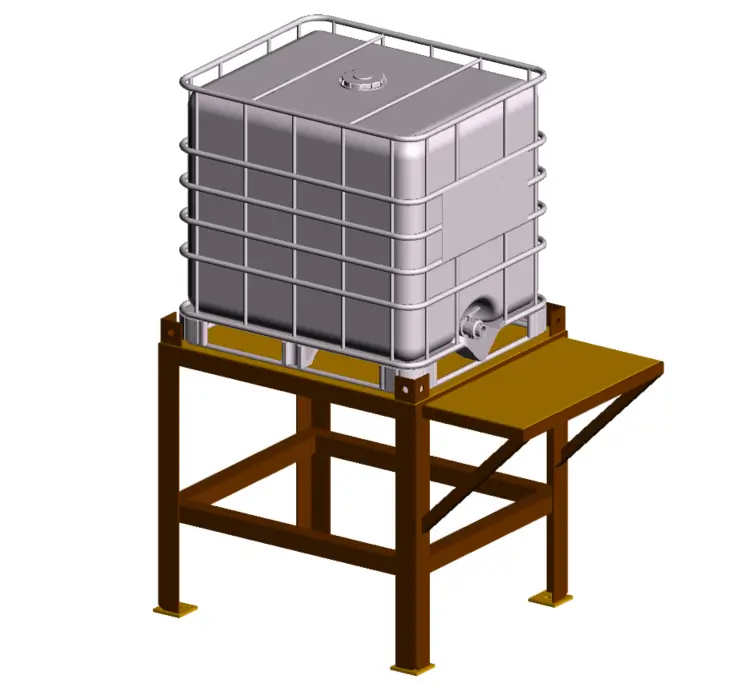

IBC Stand for Pump Suction Height

Glencore’s Hail Creek Coal Mine engaged Orana Engineering to develop the engineering design for a stand to elevate a 1,000 litre IBC from ground level, enabling the content to gravity feed to the pump suction during a major upgrade project.

Design considerations by Orana Engineering included the process and materials relevant to the IBC location, raw material requirements and painting specifications based on site standards, positioning and fit of the IBC with existing equipment and infrastructure once elevated on the stand. Height requirements for gravity feed to pump suction connection and allowance for differential grouting of feet to account for concrete falls were also taken into account.

Orana Engineering design drafters generated a 3D model of the proposed design using AutoCAD Advance Steel for client review before developing a Navisworks Model of the IBC stand and completing engineering checks for load.

Final deliverables to the client included arrangement and fabrication detail drawings of the stand with RPEQ supervision.

Light Poles Review

Orana Engineering was contacted by Glencore’s Oaky Creek Coal Mine to undertake a structural review of lighting towers situated at the Tieri township sporting oval. Existing tower bases had been buried for approximately 20 years and were displaying evidence of corrosion to anchor bolts and baseplates.

Orana Engineering conducted a review of client-supplied documentation and photographs and gathered additional information to determine repair requirements. Following the review, a letter of recommendation was provided to the client outlining repairs required for continued operation of the lighting towers, with RPEQ structural supervision.

Additional support was provided by Orana Engineering with a further review of lighting towers within the Tieri Aquatic Centre and Shopping Centre. In this instance Orana Engineering was also able to capture 3D data from light poles using its Faro 3D laser scanner. The client was presented with recommendations for tests or further analysis required.

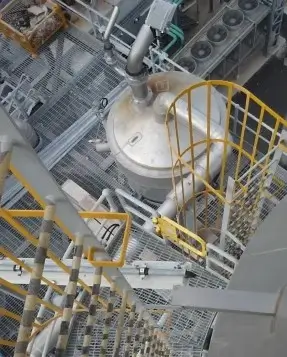

Filter Press Installation

A filter press initially planned for Glencore’s Clermont Coal Mine was relocated for installation at Collinsville Coal Mine in a trial capacity to assist in reducing the amount of tailings produced from the wash plant.

Orana Engineering was engaged to provide engineering and drafting support for the filter press installation scope of work, to assess suitability of the Clermont detailed design for construction at Collinsville and to plan and implement arrangements for the installation.

Considerations to ensure a smooth installation at Collinsville included concrete design and a structural analysis. Calculations were also undertaken to determine design wind and earthquake loads for the site to Australian Standards AS/NZS1170.2 and AS1170.4.

Orana Engineering design drafters produced a new site plan showing set-out of the filter press slab with new and existing underground services detail incorporated, with RPEQ Supervision.

Sampler PRT Documents

Process engineering personnel at Glencore’s Oaky Creek coal mine identified a need for review and gap analysis of existing coal sampler PRT (Production Resources / Tools) SAP documents, to determine where these differed from the recommendations of the original equipment manufacturers (OEMs) and from the PRTs of other Glencore sites.

The assistance of Orana Engineering was sought in conducting the review and documenting differences or gaps identified, for further discussion with site engineering contacts. Outcomes from the analysis were documented in the form of a Gap Analysis Register for client review.

With client approval, revised or additional PRT’s were developed by Orana Engineering as required to close all gaps, with changes then presented to the client to determine any final modifications to be made prior to handover.

.jpg)

Fire Hydrant Extension

Personnel at Origin Energy’s Darling Downs Power Station contacted Orana Engineering seeking assistance in reviewing regulatory requirements of fire protection systems (detection, alarms, hydrants, emergency exits) relevant to areas of the site not fully protected by existing systems due to distance or obstruction.

Orana Engineering’s design was required to tie into the existing potable water fire line to supply a new fire hydrant / hose reel, while meeting operational fire-fighting requirements compliant with Australian Standards

Orana Engineering completed mechanical engineering, calculations and hydraulic modelling for review by a third party Fire Systems Designer and verification by an RPEQ Fire Engineer. Orana Engineering also undertook pipework design and drafting with RPEQ sign-off.

Deliverables to the client comprised a scope of work document, a testing / commissioning plan, budget estimate cost proposal for installation and building certification, and provision of a drawing set for the fire water extension.

Clarified Water Upgrade

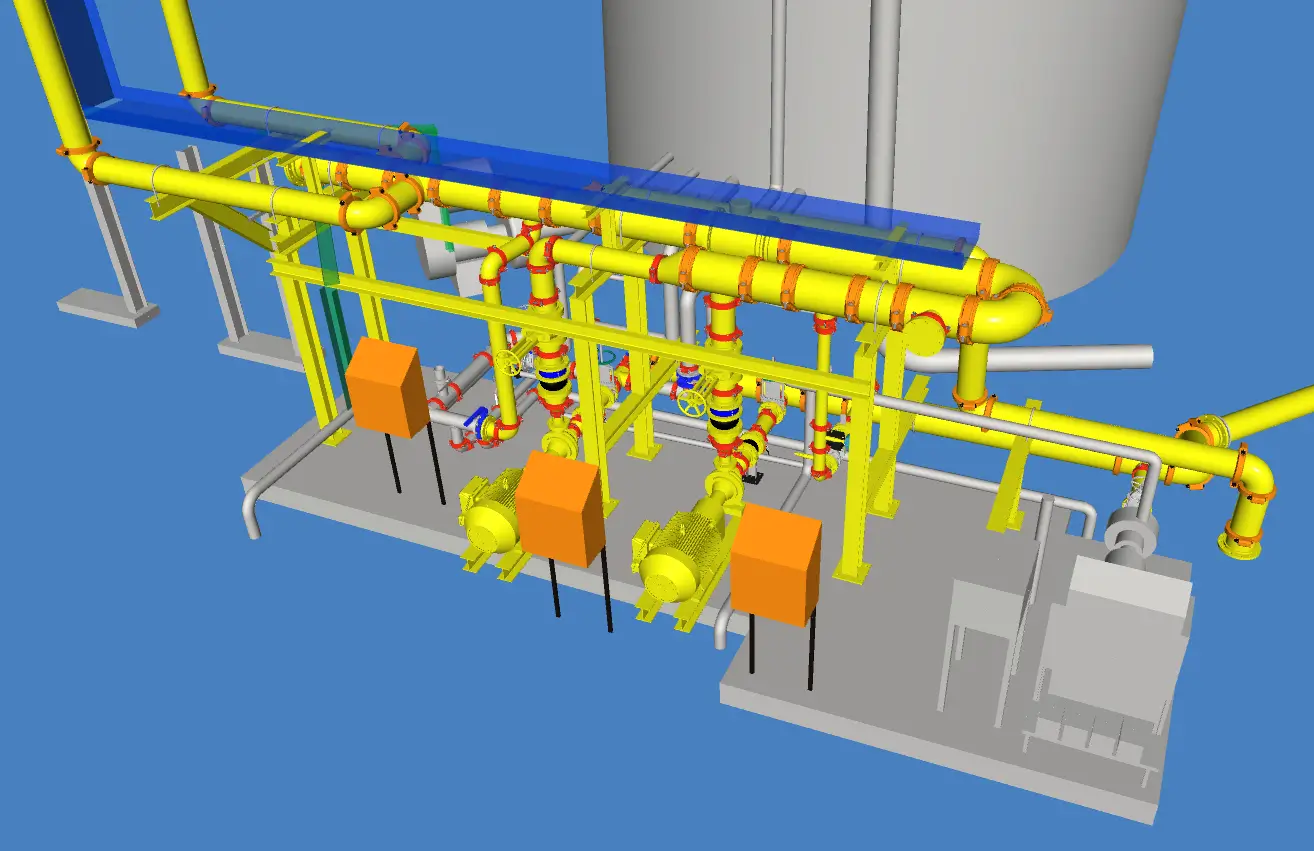

Orana Engineering was consulted by Glencore’s Collinsville mine to assist with an upgrade of its CHPP washdown water distribution system. The CHPP clarified / raw water is supplied from either an anti-pollution pond or the raw water Sunwater pipeline, with the wash water distribution network delivering water to the yard area, CHPP washdown sprays, lime / flocculant dosing or conveyors for spray bars and washdown.

Following hydraulic modelling, Orana Engineering’s mechanical engineers delivered a design with improved flow and pressure, (increasing capacity from 375 to 700 cubic meters per hour) while structural engineers produced SpaceGASS modelling of pipe supports and 3D modelling of the discharge structural steel pipe rack. Additionally, a Functional Specification or Function Description was produced for integration of the design into the plant's control system.

Project deliverables included an Equipment Register, Scope of Supply, detailed Construction and Installation Scope of Work for Tender, Functional Description and detailed design drawings.

C22147 Water Destruction

Glencore’s Collinsville Open Cut mine utilises sprinklers to partially destroy Acid Mine Drainage (AMD) water generated. Existing sprinklers were effectively moving the AMD water, but at a slow rate. Orana Engineering was contacted for assistance in designing a system to increase the existing sprinkler arrangement from 67 to 200 units, capable of dewatering up to 9.45ML per day, while utilising a minimum of pumps and nozzles.

Orana Engineering mechanical and electrical engineers gathered data and undertook hydraulic modelling in developing a sprinkler design to increase water surface area while decreasing maintenance and failure rates of existing nozzles.

3D modelling of the design was presented to the client along with RPEQ supevised detail design drawings.

Sewage Treatment Plant Concrete Slab

CS Energy engaged Orana Engineering to provide engineering and drafting support in documenting the scope for onsite civil, electrical (earthing) and mechanical (shade sail and drain piping) supply and installation at its Kogan Creek Power Stations Sewage Treatment Plant.

The basis of design was provision of detailed design engineering of a bunded concrete slab to house two 22kL aerated tanks and a 20 foot container. The slab design was to include an effluent drainage system with a new discharge pipe to be connected to the existing underground wastewater drainage network. It was planned to remove existing tanks and pumps and the design scope prepared by Orana Engineering was to include details for filling and capping the residual drainage pipes and holes.

Design drawings generated by Orana Engineering personnel to support the scope of work included a general arrangement, a detailed drawing and a revised layout drawing.

.jpg)

Oily Water Pond

Origin Energy’s Talinga Gas Plant oily water system treats water created during the gas compression process. Effluent from the system is pumped into the water-gathering network, delivering water to the main water treatment plant.

Orana Engineering was engaged by Origin Energy to evaluate the oily water system and conducted a high level assessment of options to reduce the risk of uncontrolled release of contaminated water from the wetlands system that was controlled by interim means.

Outcomes were presented to the client summarising options to reduce or eliminate identified risks. Orana Engineering subsequently provided detailed mechanical and electrical design and drafting for the approved option.

Deliverables for the project included a basis of design document, detailed design and a revison of the Wetland Operations & Maintenance Manual.

Warehouse Delivery Area

Glencore’s Collinsville Open Cut Mine engaged Orana Engineering for assistance with engineering design of a new concrete slab to allow for driving, loading / unloading of forklifts and delivery trucks at its warehouse building. The design accounted for tie-ins to existing slabs and a surrounding security fence with cantilevered sliding gates on western and eastern sides of the area.

Orana Engineering’s involvement comprised gathering of additional site data and drawings on existing slabs, reviewing geotechnical and ground survey data for conditions in the area, liaison with the client and plumbers etc to confirm area runoff and underground services, as well as engaging vendors of precast concrete barriers, sliding gates and mesh fencing.

Preliminary sketches for client review and discussion were produced by Orana Engineering’s design drafting personnel, followed by concrete general arrangement and detail drawings and a structural detail drawing ‘issued for construction’ with RPEQ Supervision.

Boiler Structural Brace

CS Energy’s Kogan Creek Power Station was experiencing intermittent lateral vibration in the structural bracing of two of its boilers. The assistance of Orana Engineering was sought in conducting a structural and vibrational engineering review of the affected plant to determine the source of the issue. The review included SpaceGASS modelling of the local structure surrounding the bracing to assess loading and determine member sizing. A modal vibration analysis was completed to determine the natural frequencies of the plant and structural bracing.

Following review, the option of installing cables for the bracing was discounted and it was recommended that new bracing for structural members be installed and connected to the midpoint on either side using a custom designed clamped fitting (to avoid welding to existing loaded brace) and installing a new cleat at the main structural member. The design solution increased the lowest natural frequency vibration mode shape for the structures and also reduced visible deflection.

Orana Engineering deliverables for the project included a Boiler Structural Beam Plan Arrangement and detail drawing ‘issued for construction’.

Brine Concentrator Drain Pump System

Orana Engineering was invited by MFE to provide an estimate for subcontract works for the Veolia Water brine concentrator drain pump system at Kenya Water Treatment Plant.

Brine concentrators at the plant periodically release high temperature and corrosive wastewater to floor sumps to control or monitor processes. The PVC pipework from floor sumps had become unserviceable due to the pipeline material not being rated for high temperatures. The existing drainage pipeline needed to be replaced with a durable system capable of withstanding high temperature corrosive wastewater.

Orana Engineering’s involvement in the project encompassed provision of engineering support (hydraulic, mechanical, civil and electrical design) and drafting support including revision of existing drawings and generation of new hydraulic, mechanical, civil and structural drawings with RPEQ supervision.

Brine Concentrator Engine Bay Crane

Veolia’s Kenya Water Treatment Plant contacted Orana Engineering for assistance with engineering design and drafting of a manual pull-along crane utilising existing support beams and able to travel in both long and cross travel directions. It was proposed for the fabricated cranes to be installed in each of the treatment plant’s three brine concentrator engine bays.

A member of Orana Engineering’s mechanical engineering team attended site to inspect existing infrastructure, take measurements and gather information. Upon return to Orana Engineering’s Chinchilla office the site data was reviewed, structural engineering calculations performed and information provided to the drafting office for translation to general arrangement and detailed design drawings suitable for fabrication purposes.

Culgoa Weir Gates

Orana Engineering was contacted by Sunwater to design a frame capable of supporting two hydraulic over-shot gates to be installed on the existing Culgoa Weir structure. The purpose of the gates was to allow water flow downstream when open. Hydraulics were to be driven via a power pack on the back of a utility vehicle.

Orana Engineering undertook mechanical design of the gate frame including reviews of weir flow calculations and load scenarios. Structural design aspects involved calculations, selection of member sizes, bolting details and connections as well as modelling of the frame in SpaceGASS with applied load cases and AS4100 analysis.

Orana Engineering designers produced a 3D model of the frame and gate arrangements and drawings suitable for handover to a fabricator for installation.

2ML Diesel Tank Bunk

Glencore’s Newlands Open Cut Coal Mine was investigating methods to update bunding for a 2 million litre diesel storage tank and engaged Orana Engineering to assess the existing bund while also considering requirements for a future fuel farm and compliance with Australian Standards.

Orana Engineering reviewed client-provided documentation and information gathered from site including drawings and survey data of the existing earth bund and details of underground services. Assessment of suitable liner options and an evaluation of the existing earth bund for necessary repair was also conducted along with considerations for tie in of the bund liner to existing structures. Orana Engineering delivered a file note for the site Project Manager to review compliance options.

Brine Concentrator Stair Tower Rescue Lift Points

Veolia Water’s Kenya Water Treatment Plant contacted Orana Engineering to provide engineering and design drafting assistance in relation to installation of fall-arrest rescue anchor points to the brine concentrator stair tower.

Orana Engineering mechanical personnel undertook a review of applicable codes and standards in order to identify key safety considerations in the use of fall arrest systems. Calculations were performed on existing structural members locally to determine beam capacity for the addition of lugs at 6 points as identified by the client.

Deliverables for the project included an RPEQ supervised design for manufacture and installation of the lugs, revision of existing client drawings to reflect design changes and creation of a new drawing including both general and detailed information for new lug locations.

Conveyor Commissioning Sheets

Anglo American Grosvenor Mine sought the assistance of Orana Engineering in developing check sheets for reference by site personnel during underground conveyor commissioning processes.

Firstly, Orana Engineering produced an extensive Inspection & Test Register covering the civil and mechanical components of the various conveyor systems on site. The Register provided a breakdown of all system areas required to be covered by the commissioning check sheets.

Close communication between site and mechanical personnel from Orana Engineering ensured a comprehensive list of inspection and testing tasks was produced, covering all of the checks to be undertaken during conveyor commissioning.

From the approved Inspection & Test Register, approximately 190 individual check sheet templates were issued for review and approval by site management prior to use by mine personnel during the commissioning process.

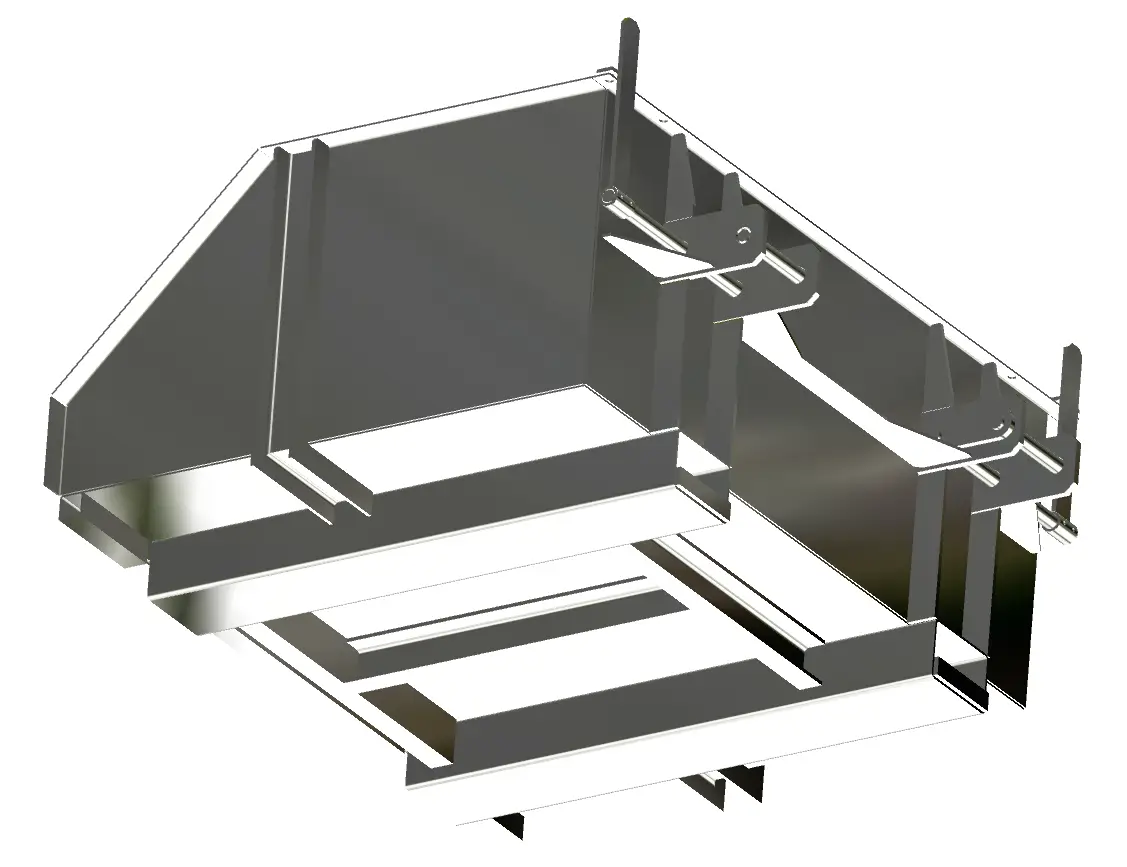

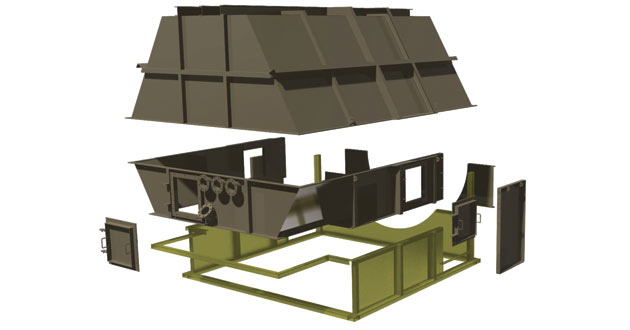

Telehandler Bin Design

At the request of Carborough Downs Coal, Orana Engineering initiated the design of a new bin for collection of used coal samples within the CHPP. Up until that point practice had been to transport samples to the bin by wheelbarrow, with the barrow then lifted (rather than levered) and the contents tipped into the bin.

Carborough Downs requested that Orana Engineering design a bin to enable wheeling of the barrow into the bin such that the contents could be tipped without the need to lift the barrow. Once full the bin would be collected via a telehandler and emptied onto the rejects pile.

Orana Engineering designers prepared a high level 3D model of the proposed telehandler bin, a 3D design of the lifting and pivot mechanism and bin fabrication, detail and assembly drawings with RPEQ Supervision.

Orana 4 Pump Station

Veolia Water engaged Orana Engineering to look into options for a replacement pump station at its QGC Kenya Central Water Treatment Facility.

High level concept design investigations were initiated for options to replace the existing diesel driven manually controlled pump system for transferring brine from the site's Orana 4 Pond to the plant for treatment. Both a land based primed pump station and a water based floating pump station were given high level consideration. A detailed concept options report was developed for review and consideration by site stakeholders.

Secondary Spirals Monorail Design

At the request of Glencore Collinsville Coal Mine, Orana Engineering performed engineering design and drafting for a new monorail to be installed within the CHPP secondary spirals area. Orana Engineering’s assistance with the project included SpaceGASS modelling of the area and completing initial engineering and analysis for the proposed monorail while considering any effects on the existing structure and performing calculations and structural design checks to Australian Standards AS4100, AS1170 and AS1418.18.

Lifting vendors were consulted for monorail trolley and chain block options which ensured the most appropriate selections for the Collinsville application.

The designers at Orana Engineering produced a 3D model which was issued to the client for review and feedback. The monorail was fabricated and installed by others to Orana Engineering detailed design drawings and then load tested with subsequent deflection results meeting the requirements of Australian Standards.

.webp)

Filter Line Upgrade

Process Engineering personnel at Glencore’s Collinsville Coal mine contacted Orana Engineering for engineering support on various projects associated with an upgrade of the piping in its ultrafine circuit. These included incorporation of tee-offs to in situ lines, and additional pipe runs.

Orana Engineering utilised existing 3D scan data to model a new pipe route and to provide concept general arrangement drawings to the client. With this information site personnel had sufficient data to liaise with vendors regarding new equipment selection.

Orana Engineering’s estimate also allowed for detailed design of RPEQ supervised drawings to allow the piping to be fabricated and installed.

Additionally, Orana Engineering conducted a structural assessment of the horizonal belt filter (HBF) to support a proposed viper roller unit.

_1.webp)

Ash Water Treatment Plant

CSE Energy’s Kogan Creek Power Station identified that due to higher than normal rainfall its decant pond had neared capacity and was unlikely to evaporate in an acceptable timeframe by either natural means or with the assistance of fans. It was proposed to reuse the water on site, however due to a concentration of suspended silt the decant water required treatment before being returned to the plant. The solution was sourcing and installation of a containerised water clarification plant.

Orana Engineering was contacted for provision of electrical engineering design and support for power and control of the proposed ash water treatment facility as well as mechanical engineering input with pumping, piping and tank design for water supply and tie-in to existing infrastructure.

CHPP Projects - Water Balance

Orana Engineering was requested by the CHPP Manager Capital Projects at Glencore’s Collinsville coal mine to provide engineering and scoping assistance with respect to the mine’s underground water service repair and upgrade scope of work.

A member of the Orana Engineering mechanical engineering team attended site to liaise with onsite stakeholders, operators, plumbers and surveyors and to gather information on raw water and potable / fire water supply issues being experienced.

Upon return from site, a high-level engineering review was conducted along with detailing of raw water and potable / fire water scopes. Basic hydraulic modelling was also carried out to identify pressure spike issues and water hammer. Following review completion, the client was provided with a basis of design and a summary of Orana Engineering’s findings and recommendations.

CHPP Structural Repairs - CBN302

Glencore's Collinsville Coal Mine engaged Orana Engineering to develop a deconstruction safe work methodology for demolition and deconstruction of the CBN302 reject bin, along with appropriate risk assessment documentation based on the deconstruction methodology.

Key considerations were ensuring that the bin and structure supporting the conveyor head end were maintained in a safe and stable condition during deconstruction and that the risks of stored energy in the curved bin shell plates was managed through the steel thermal cutting process (avoiding steel plate spring-back hazards).

Orana Engineering’s basis of design determined the necessary steps to safely remove the redundant CBN302 reject bin.

Detailed design and engineering provided by Orana Engineering included 3D modelling of the reject bin and structural steelwork to assist in preparing the methodology images.

CHPP Structural Repairs - Clevis Plates

The CHPP Structural Supervisor at Glencore’s Collinsville Coal Mine requested the services of Orana Engineering in completion of a structural review and provision of a replacement methodology for the CCV101 Trestle Clevis Plates.

Orana Engineering’s consultation included a structural review of documents and existing drawings, identification of load-bearing elements and weak points, analysis of existing design and indication of necessary modifications. Additionally, the review included development of a strengthening plan and methodology utilising temporary bracing and support systems to lift the structure for trestle clevis plate replacement and avoid working under suspended loads using props.

Outcomes from the project included a letter of recommendation with instructions for the trestle clevis plates replacement works, including notes and methodology, mark-ups of site photos and drawings to illustrate the proposed replacement methodology.

CHPP Maintenance Work Instructions

The CHPP Maintenance Superintendent at Glencore’s Collinsville Coal Mine sought the assistance of Orana Engineering in developing Work Instructions for various maintenance processes carried out within the CHPP.

Two Orana Engineering Mechanical Engineers were assigned to attended site on multiple occasions during scheduled plant shutdowns to review processes and either update existing or generate new Maintenance Work Instructions for multiple functions and locations within the CHPP.

Finalised Work Instructions were subsequently presented to the client for final approval prior to incorporation / upload into Collinsville’s resource library.

CHPP Monorail Assessment

Glencore Coal Collinsville sought assistance from Orana Engineering in assessing multiple monorail designs within the CHPP area. The design review was to determine compliance with Australian Standards, including analysis of the structural capacity of each monorail, taking details from design drawings, 3D scans of the plant and physical measurements.

Fifteen monorails in total were assessed via visual and non-invasive means to determine their general state. Photos were cross-referenced with 3D scan data of the plant and existing structural drawings, with a structural assessment completed on all monorails to AS1418.18 using SpaceGASS and spreadsheet calculations.

Deliverables to the client upon conclusion of the study included a summary of design review results and recommendations for remedial action. Results from the assessment allowed updated certified as-built drawings of each monorail to be produced.

Compressed Air Upgrade

Anglo American’s Moranbah North CHPP operations personnel contacted Orana Engineering to investigate problems with low compressed air pressures and air flow rates. There were additional concerns regarding compressor reliability associated with the operation of equipment, valves, tooling, maintenance and instrumentation.

Orana Engineering conducted an onsite investigation which included preparing as-built drawings of the high-level compressed air distribution network within the CHPP. A review of historic transmitter data for the system was also carried out to identify issues and bottlenecks. System performance was also reviewed against site-checked pressures and engineering flow rate and pressure loss.

Upon conclusion of the investigation a summary of findings and recommendations was presented to the client encompassing as-built drawings, calculations, a summary of works and recommendations for resolution.

Rotary Breaker Facility Upgrade

The layout of the Rotary Breaker Reject Facility at Glencore's Collinsville Open Cut Coal Mine required loaders to be fully articulated to access and remove material from the reject bin. Orana Engineering provided a proposal for re-orientation of the facility 90 degrees, allowing loaders to drive directly into the bin area for removal of material.

The aim of proposed changes was a reduction in safety risks posed by awkward positioning of the facility. The design scope included modifying the existing reject chute to reduce blockages and other operational issues. The new design allowed for greater clearance of reject material and with the chute supported off the side wall of the facility to ensure structural integrity.

Orana Engineering designers prepared a 3D model considering limited vehicle interactions, optimising loading operations and minimising risks of structural damage. IFC drawings and project management were provided to complete the installation through to commissioning.

Crusher Gearbox

At the request of Glencore’s Collinsville Open Cut Coal Mine, Orana Engineering personnel attended site to perform a visual inspection on the CCR106 Abon Crusher following failure of the gearbox-to-crusher mounting studs.

The focus of the inspection was assessment of damage to impacted structural steel members on the crusher floor which had resulted from gearbox movement during the failure, and to troubleshoot the reason for the stud failure.

A summary of observations and supporting photos gathered during the inspection was compiled for presentation to the client. In addition, Orana Engineering provided a professional opinion regarding possible scenarios leading to failure of the mounting studs and offered recommendations for additional checks on the integrity of the crusher infrastructure.

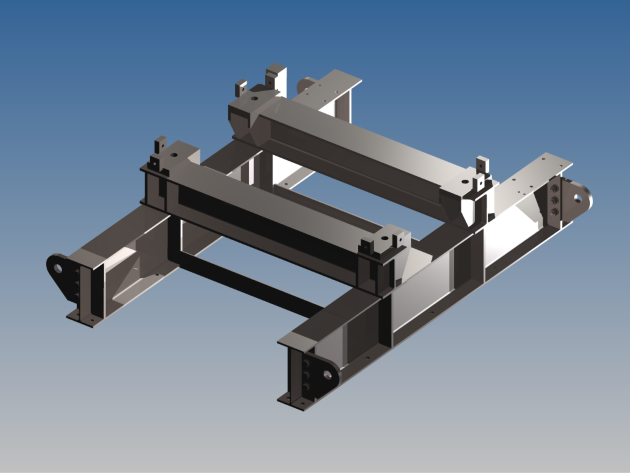

Skip Rotator

Glencore’s Ernest Henry Mine proposed to install a skip rotator to enable periodic maintenance and refurbishment of its underground ore hoist skips. The skip rotator was to consist of a removable access platform, a two-part skip cradle, plus a pneumatic drive motor and brake assembly supplied by the compressed air system. It was envisaged the rotator would enable ore skips to be rotated without the use of a 20T mobile crane and a 32T forklift which was the established method.

Orana Engineering was requested to provide mechanical and structural design and drawings of sufficient detail to allow fabrication, installation and operation of the skip rotator. In addition, Orana Engineering mechanical design personnel generated a model of the skip rotator using Autodesk Inventor which provided the client with a 3D overview of the design.

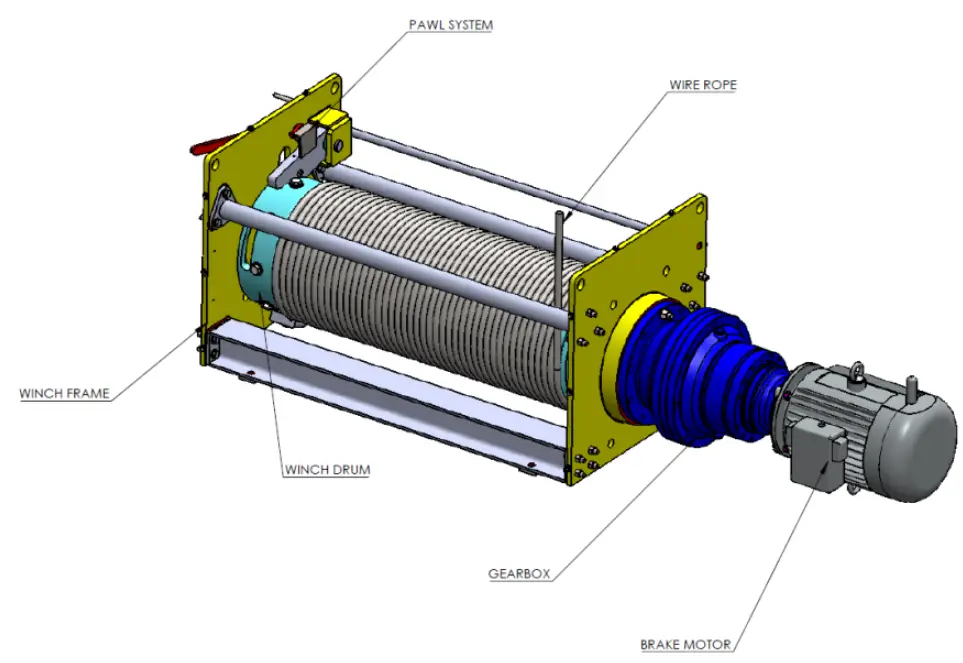

Conveyor Counterweight Design

Orana Engineering was approached by Glencore’s Oaky Creek Coal CHPP personnel to supply a cost estimate for development of modified winch systems for its CV15 and CV16 take-up towers.

The scope of work included provision of mechanical, structural and electrical engineering and design drafting for inclusion of electric take-up winches to facilitate lowering of conveyor counterweights during maintenance activities.

Structural and civil checks were conducted to account for expected force changes caused by additional sheaves and electrically driven winching effects on the structures when compared to the existing gravity take-up applications. The installation was configured and commissioned into the DCS control system by Orana Engineering's control systems engineers.

In addition to mechanical and electrical detailed design drawings, Orana Engineering provided equipment recommendations and specifications, bill of materials and a Safety In Design Report upon finalisation of the design development cost estimate.

LOM Pit Air Audit

Deficiencies with existing and Life of Mine (LOM) pit compressed air systems at Xstrata Coal’s Oaky No.1 Underground Coal Mine had been resulting in numerous production delays. Orana Engineering was engaged to investigate, analyse and provide delivery strategies for ensuring acceptable air pressures and flow rates were achieved for remaining mining activities within the site LOM Plan.

Considerations for improvement included additional compressors and piping system changes where required to achieve improved compressed air flow.

Orana Engineering conducted analysis using isothermal flow equations with a selection of these then verified via hydraulic modelling. Conclusions from modelling identified maximum allowable pipe lengths and flow rates for optimal compressed air flow, with subsequent improvement recommendations provided to the client.

LOM Raw Water Supply Plan

Raw water pressure problems within the longwall and development mining areas at Xstrata Coal's Oaky No.1 Underground Coal Mine had resulted in numerous production delays. At the client’s request, Orana Engineering undertook a Life of Mine (LOM) study to develop a raw water supply plan based on strategic booster pump positioning.

Hydraulic modelling was subsequently completed by Orana Engineering based on the Raw Water Supply Network LOM Study and taking into account the effects of firefighting demand pressures, flow rates and water hammer.

Results were summarised in a pump positioning flow sheet and a pump positioning plan to illustrate recommended current and future booster pump positions required to achieve minimum raw water supply pressures and flow rates.

Reagents Tank Farm Rectification

Due to the existing system not being compliant to site standards, BMA Saraji Mine had constructed a new reagents system for the supply of diesel and MIBC into their CHPP. Following construction, several attempts were made to wet commission the system however these were unsuccessful due to multiple problems identified by the client.

Orana Engineering was requested to undertake a complete design review of the reagents system, to outline problems with the design and to provide a scope of work to rectify these such that wet commissioning could be completed.

At the conclusion of the review a bill of materials for the commissioning scope of work was provided, detailing procurement specifications for required mechanical equipment and spares.

Mine Dewatering

At the request of Carborough Downs Coal, Orana Engineering initiated an investigation into an upgrade of dewatering and sump transfer systems for multiple underground and surface mining areas at the then Vale-owned mine. Existing pumping systems were deemed not fit for purpose and the client required options for solutions capable of handling projected maximum rainfall and underground water-make intensities and preventing ingress of water to mine workings during such events.

In addition, Orana Engineering was requested to formulate a concept design for dewatering of underground workings during longwall mining operations and to offer alternatives to the existing system.

At the conclusion of investigations, the client was provided with various concept designs for both surface and underground dewatering options along with equipment recommendations and budget estimates.

Tertiary Crusher Upgrade

Orana Engineering was called upon by Glencore's Collinsville Open Cut Coal Mine to provide engineering, drafting and project management for an upgrade to its tertiary crusher and supporting structure, involving multiple site visits to assist with on-site aspects of the construction phase.

The basis of design included engineering and drafting to understand and develop the FEED and scope for the capital project, designing of the support structure to install the replacement tertiary crusher and provision of package management for the entirety of the project.

Some of the primary deliverables for the project included 36x IFA / IFC drawings for the tertiary crusher structure upgrades, a critical spares list (including liaison with vendor), fabrication scope of work for tendering, a Change Management document, and a Risk Assessment.

PPP027 Plant Feed Upgrade

Century Mining’s zinc tailings treatment operation is situated in north-west Queensland and is the largest tailings retreatment operation in Australia. Century sought the services of Orana Engineering in providing engineering support for its PPP027 Plant Feed Upgrade Project.

The project scope encompassed multidisipline engineering design for the upgraded plant feed pumping system including Weir Warman pumps. The client also requested a mechanical engineering review into combined use of poly lined, rubber lined and UHMWPE piping supported by Orana Engineering’s liaison with product vendors. Electrical design and site based support was delivered by Orana Engineering to suit the requirement of the project resources and timeline. Civil and structural engineering design was completed for the underground services and concreted area and footings.

.webp)

QGC AIWT Design Review

Hutchinson Builders Toowoomba was contracted to deliver portions of the Water Aquifer Injection Trial at QGC’s Woleebee Creek site. Prior to construction, Hutchinson Builders engaged Orana Engineering to perform a design review of all mechanical technical documentation associated with the Pond Transfer Pump Station.

The review aimed to determine whether sufficient detailed information had been provided to allow Hutchinson Builders to successfully complete construction. Orana Engineering completed and issued a design review report which detailed recommendations from the review.

During construction, Hutchinson Builders also engaged Orana Engineering to perform an inspection of a buried HDPE pipeline and to assess the construction of the pipeline against requirements of engineering drawings and specifications.

10M TAGS Sled

At James Cook University, MBD Energy operates a research facility investigating methods of cultivating and harvesting algae. To facilitate greater control of the algae agitation sleds, Orana Engineering was engaged to design and commission mechanical, electrical and control systems that would enable agitation sled velocity and frequency of travel to be automated.

The system was designed and implemented by Orana Engineering utilising Allen Bradley Powerflex VVVF drives and a Controllogix’s PLC with an RSView SCADA interface.

Orana Engineering was able to help MBD Energy improve the efficiency and quality of their research results by providing technical knowledge and assistance through our control systems, electrical engineering and mechanical engineering services.

CHPP Conveyor Capacity Audit

Vale at Carborough Downs Coal Mine required quantifying of current and possible future capacities of product conveyors at their coal processing plant in Central Queensland and high level recommendations to achieve increased plant tonnages.

Orana Engineering completed an initial site visit to gather the necessary information for a review of each of the conveyors. Engineering checks were completed to identify bottle-necks in the conveyor design such as motor power, drive equipment, belt curves, GTU mass, belt speed, belt capacity, belt tensions and electrical supply.

Orana Engineering issued a detailed report at completion of the study and provided concept level equipment modification recommendations for tonnage ranges advised by Carborough Downs Coal Mine.

Conveyor Upgrade Project

Carborough Downs Coal Underground Mine had transitioned from a bord and pillar mining system to longwall. The result was a need to upgrade capacity of the coal clearance conveyor system. Orana Engineering was engaged to provide Client Engineering assistance to deliver underground conveyor equipment to meet the longwall production schedule.

Orana Engineering monitored vendor design progress against the schedule, performed design reviews to ensure correction of errors prior to final client approval, monitored and managed fabrication and delivery schedules and managed budget and variations in line with the contract.

By co-ordinating with the client’s installation group and managing the vendor in line with the client’s schedule, the conveyors were successfully installed and made available for longwall production.

Crane Lifting Beam

The mother beam of the 40T ship loading crane at the Port of Townsville was nearing the end of its 30 year service life. Xstrata Copper engaged Orana Engineering to redesign the beam based on the existing beam and to incorporate changes in compliance with latest regulations.

After fully modelling the mother beam using Autodesk Inventor, RPEQ approved shop detail drawings were produced. Electrical monitoring systems were introduced to enable crane operators to confirm when the mother beam was fully engaged with various attachments, and control wiring to the beam was redesigned to include two cable drums whereas the original had three.

Mechanical redesign included a failsafe back-up locking system and design improvements highlighted by feedback from maintenance personnel.

Crusher Circuit Upgrade

Eloise Copper Mine purchased a Metso dual deck vibrating screen to replace an existing smaller screen and a second Omnicone cone crusher to provide a secondary crushing circuit for increased production and efficiency. Orana Engineering was engaged to develop a design solution and detailed drawings for the secondary crushing circuit which utilised as much existing equipment as possible.

Orana Engineering was able to provide an efficient, practical design solution while minimising the associated design costs to provide site personnel with information required to refurbish and install the conveyor equipment necessary for the crushing circuit.

Orana Engineering successfully completed the design within a tight project time frame and produced in excess of 100 detailed drawings.

Cyanide Tank Upgrade

Carpentaria Gold identified that bunding around their Ravenswood cyanide storage tank was inadequate. Sodium Cyanide, used in the gold recovery process, is potentially lethal to humans and animals and detrimental to the environment. It is necessary to ensure it can be safely contained in an emergency.

Orana Engineering provided an innovative solution comprising a smaller tank fitted inside the existing tank. The design minimised loss of storage capacity by providing a smaller tank for primary storage whilst maintaining the existing external tank to act as the bund.

Utilising the existing tank as a bund, Orana Engineering delivered a design that met the client brief while re-using the majority of major tie-in points and providing improved access for maintenance.

F100 Reagent Modifications

Orana Engineering was engaged by MMG's Century Mine to review a proposed reagent dosing system within the concentrator.

An investigation was conducted which included hydraulic modelling for various reagent dosing system philosophies. Results were presented for a range of design and operating conditions and three solutions were proposed meeting the client's requirements. Factoring in control system complexity and cost, Orana Engineering recommended a preferred option and a back-up option requiring only minor system modifications.

The engineering review was completed within a short timeframe and a detailed report provided to MMG detailing hydraulic modelling results and required operational settings for the offered options. MMG was able to use the results to make a decision on the solution ultimately implemented.

Fire System Audit

BMA Gregory Crinum engaged Orana Engineering to perform an audit and inspection of the Crinum underground mine surface fire water system with respect to providing adequate pressure and flow for the Crinum North conveyor system and stockpile conveyor.

Orana Engineering completed a site inspection and audit against the design drawings, with site-verified information then used for compliance assessment in line with Australian Standards. The audit included in-depth assessment of the fire water system to Australian, BMA and site Fire Management Standards. Hydraulic modelling of the fire system was also undertaken to validate existing pressure measurements.

Orana Engineering was able to make recommendations regarding compliance and system hydraulic performance, which assisted BMA in improving system capacity.

Flotation Cell Upgrade

To increase the efficiency of their concentrator, Eloise Copper Mine enlisted Orana Engineering to provide engineering and design assistance with installation of three copper concentrate scavenger cells within the existing plant.

3D models created by Orana Engineering designers were used to visually communicate solutions for new and existing equipment locations and structure arrangements. Detailing of these concept models enabled Orana Engineering to identify key tie-in locations within the plant for survey during the detailed design phase.

A multidisciplinary approach during detailed design ensured improved efficiency, with brownfield engineering challenges in relocating / connecting to existing equipment successfully achieved. Upon design completion the client was provided with an installation drawing set and scope of work.

Gold Slurry Sampler

Orana Engineering was engaged to design new sampling equipment for improved sampling effectiveness at Carpentaria Gold’s Ravenswood operations.

A site visit was undertaken by Orana Engineering design staff to accurately record critical data. This enabled designers to produce a detailed 3D model which was used extensively during interactions with the client and ensured a fluent understanding of the project scope by both parties throughout the design process.

Orana Engineering was able to integrate new sampling equipment into the existing plant whilst minimising any impact on the operation. Various challenges were overcome with the result being successful delivery of drawings for fabrication and installation of equipment, allowing improved sampling and production reconciliation whilst minimising impact to operations.

Heavy Vehicle Washdown Facility

MMG's Karumba Port Facility engaged Orana Engineering to design a heavy vehicle washdown facility to assist with management of concentrate for site vehicles and machinery. The time frame was short due to operational requirements, such that Orana Engineering worked from concept to IFC drawings in just seven days.

The design needed to accommodate a number of different vehicles from fully laden container trailers to a 30 tonne forklift, whilst also ensuring ease of facility maintenance and capture of runoff for environmental compliance.

Concept sketches were prepared, from which a detailed design was developed to meet client requirements. Through effective communication with the client Orana Engineering was able to deliver the design in a compressed timeline, to specification and budget.

Inner Bypass Valves

Orana Engineering was engaged by MMG's Century Mine to design an upgrade within the concentrator for increased flow from a flotation cell to a tailings trough.

Orana Engineering conducted a concept investigation of available options to increase the flow rate. Results were presented for a range of design and operating conditions, and a preferred option was selected for detailed design.

Orana Engineering design staff created a 3D model of the new pipeline using Autodesk Inventor. The 3D model was used to produce fabrication drawings for pipe supports, new platform and new pipe bridge. Drawings also included isometric pipe spool drawings and revised P&ID drawings.

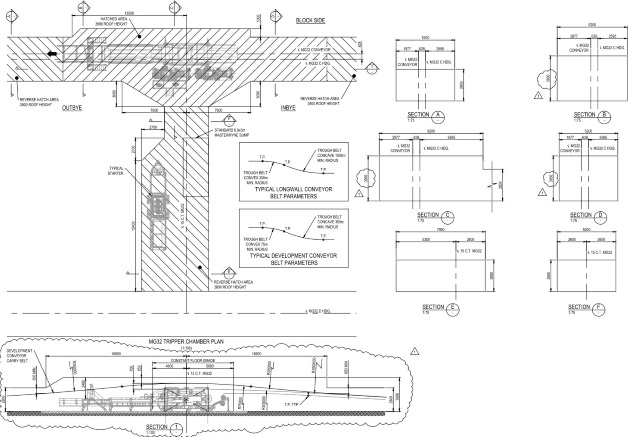

MG07 Conveyor – Chamber Design

Carborough Downs is an underground operation utilising conveyors to transport mined coal to the surface. As new longwall headings are mined, new conveyor installations are also required. Orana Engineering was engaged to complete a drive-head chamber design, ensuring adequate sizing for installation of conveyor equipment.

During initial mining of the chamber, a coal seam fault line was discovered. Carborough Downs requested that Orana Engineering develop a chamber design that maximised product mined through the fault area, while working within conveyor installation constraints. Using AutoCAD, Orana Engineering produced several design options and sketches for client approval and reference during mining processes.

Orana Engineering provided final chamber excavation drawings, which were developed into mine designs and sequence plans, by site mining engineers.

MG07 Conveyor – Civil Design

Carborough Downs is an underground operation utilising conveyors to transport mined coal to the surface. As new longwall headings are mined, new conveyor installations are also required. During installation of conveyors in an underground environment it is vital that the civil design is detailed accurately as this is the basis for locating and installing conveyor equipment.

Orana Engineering was engaged to complete this design and used AutoCAD to develop a civil design that met the client’s constraints and constructability requirements. From this design Orana Engineering produced a drawing set detailing civil aspects of the conveyor design, including floor / rib trimming, equipment hold-down details, configuration of concrete reinforcing and overall grade of concrete.

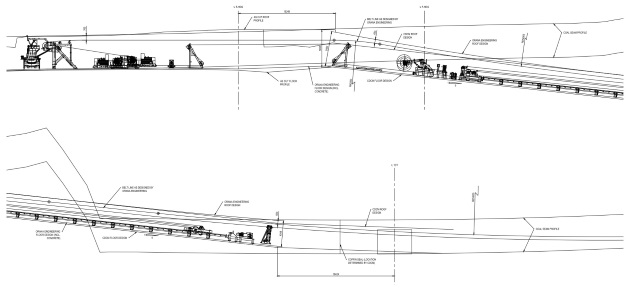

MG07 Conveyor – Development Conveyor

Carborough Downs Coal Mine is an underground operation utilising conveyors to transport mined coal to the surface for processing. As operations progress and new longwall headings are mined, new conveyor installations are also required.

Carborough Downs engaged Orana Engineering to complete a mechanical arrangement design for configuration of conveyor equipment. The design had to consider several factors, including meeting required operating capabilities, ensuring unimpeded access along travel roads and maintaining minimum belt curves.

Using AutoCAD, Orana Engineering developed a mechanical design that met client constraints and constructability requirements. From the design, a drawing set was produced detailing mechanical aspects of the conveyor design, including equipment configuration, and extensive details for selection and installation of conveyor structures, whilst minimising curves.

MG08 Development Conveyor

Carborough Downs Coal Mine is an underground operation utilising conveyors to transport mined coal to the surface for processing. As operations progress and new longwall headings are mined, new conveyor installations are also required.

Orana Engineering was engaged to design a new longwall drive-head chamber and conveyor installation, initially providing a drawing set detailing required drive-head chamber dimensions to suit the conveyor installation.

Using AutoCAD, a civil design and conveyor equipment arrangement was produced. The conveyor design had to consider several constraints, including available equipment, transfer tie-in to existing trunk conveyor, maintenance access, drainage, minimum clearances and belt curves.

Upon layout approval, AutoCAD drawings were produced detailing civil and mechanical design aspects, enabling site engineers to complete installation with efficiency while ensuring regulatory compliance.

MIA Services Audit

Orana Engineering was requested to complete an audit of water and wastewater services at BMA’s Blackwater Mine. The audit was to determine whether new go-line infrastructure would adversely impact the existing mine industrial area services, and whether additional infrastructure or upgrades were required.

Data collected from site by Orana Engineering was used to prepare a hydraulic model for each service. Modelling results, findings and recommendations were included in a detailed report outlining the capacity and utilisation of existing services to quantify available system capacity for the proposed new buildings. Additionally, Orana Engineering’s drawing revision services were utilised to formally revise site P&IDs to As Built, incorporating mark-ups made during the site visit.

MIBC & Diesel Upgrade

The purpose of the Reagent System Upgrade at Oaky Creek was installation of new reagent storage tanks, discharge / delivery pumping systems and automated flow control distribution manifolds for the delivery of each reagent to the nominated process connections.

Orana Engineering performed mechanical, electrical and control systems design, drafting and engineering for the project. The primary deliverables included scope of works, construction drawings, functional specification, BOM, spares lists and equipment / instrument data sheets.

Orana Engineering managed the onsite commissioning of the system and provided a system handover to operations for implementation. An Operation & Maintenance Manual and Hazardous Area Dossier were provided on project completion.

Mill Gear Box Frame

The IMT project team at MMG’s Century Zinc operations enlisted the assistance of Orana Engineering to produce a set of fabrication drawings for an existing gear box frame that required replacing. The frame had been in operation for some time, however there were no detailed drawings available for construction of a replacement unit.

The design staff at Orana Engineering created a detailed 3D model using client-supplied photos and sketches, enabling designers to produce 2D fabrication drawings for approval. A review of the drawings was conducted by the client to confirm the layout and accurate alignment with the existing installation on site. Following minor adjustments, As-Built status drawings were reissued to the client, accurately capturing detail of the existing frame.

Onsite Accommodation Camp Services

Orana Engineering was engaged by Oaky Creek Coal to assist in design and construction of onsite camp accommodation, including an HV substation for power and potable water supply.

The brief included mechanical, electrical and control systems design, drafting and engineering for the project. Deliverables included scope of works, construction drawings, functional specification, drawing and equipment registers, commissioning and operating spares lists and equipment and instrument data sheets.

Orana Engineering provided PLC configuration and commissioning assistance for pump control, acted as Client Representative during construction, managed onsite commissioning of the system, and provided a handover to operations for implementation.

Operation & Maintenance Manuals for potable water storage and the HV substation were provided upon completion.

SAG Mill Cover

BHP Billiton Cannington Mine, is a significant miner and exporter of silver and lead concentrate. Orana Engineering was engaged to provide workshop fabrication drawings for a replacement cover to address corrosion issues around flanges and access openings on the existing SAG mill trommel sump cover.

Following a site visit to obtain measurements, photos, drawings and documentation, the Orana Engineering design drafting team created a detailed 3D model of the existing structure incorporating new components to produce a set of detailed shop fabrication drawings, while also revising multiple existing drawings. These drawings were reissued for construction after receiving client approval.

The new cover sections and access panels improved the safety of trommel operation while also reducing inspection and maintenance time.

Tailings Pumping System - As-Built

At the completion of tailings pumping upgrades of the main CHPP and Module 4 CHPP at Oaky Creek Coal, Orana Engineering received as built drawings from site and was requested to make electronic revisions for upload into the client’s Drawing Management System.

Over 80 drawings had received red pen site mark-ups indicating either that the design had been constructed as per the drawings, or highlighting design changes made during the construction phase of the project. Orana Engineering reviewed these mark-ups and formally revised all drawings to as built status, incorporating the site mark-ups.

The final set of drawings was uploaded to the client’s Drawing Management System ensuring site personnel had access to the latest as built drawings.

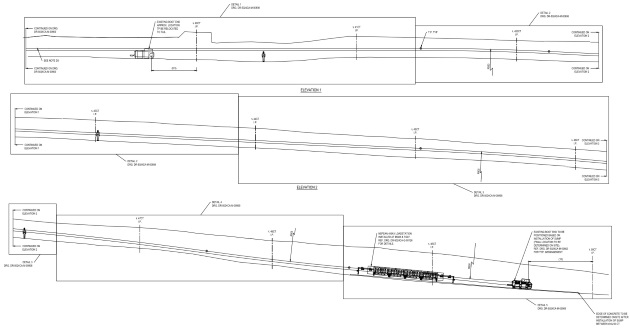

TC04 Trunk Conveyor Extensions

Carborough Downs Coal Mine is an underground operation utilising conveyors to transport raw material to the surface for processing. As operations progress new trunk conveyor extensions are required.

Orana Engineering was engaged to assist with the process of extending an underground trunk conveyor. This involved using survey data of the conveyor heading and designing a suitable belt profile, utilising minimum conveyor curves identified in the conveyor power and tension analysis.

Orana Engineering produced a set of drawings detailing the belt profile, conveyor structures and locations for roof bolts that the structures would be suspended from. These drawings enabled site engineers to complete the conveyor structure installation and conveyor extension with minimal risk of error and conveyor tracking problems.

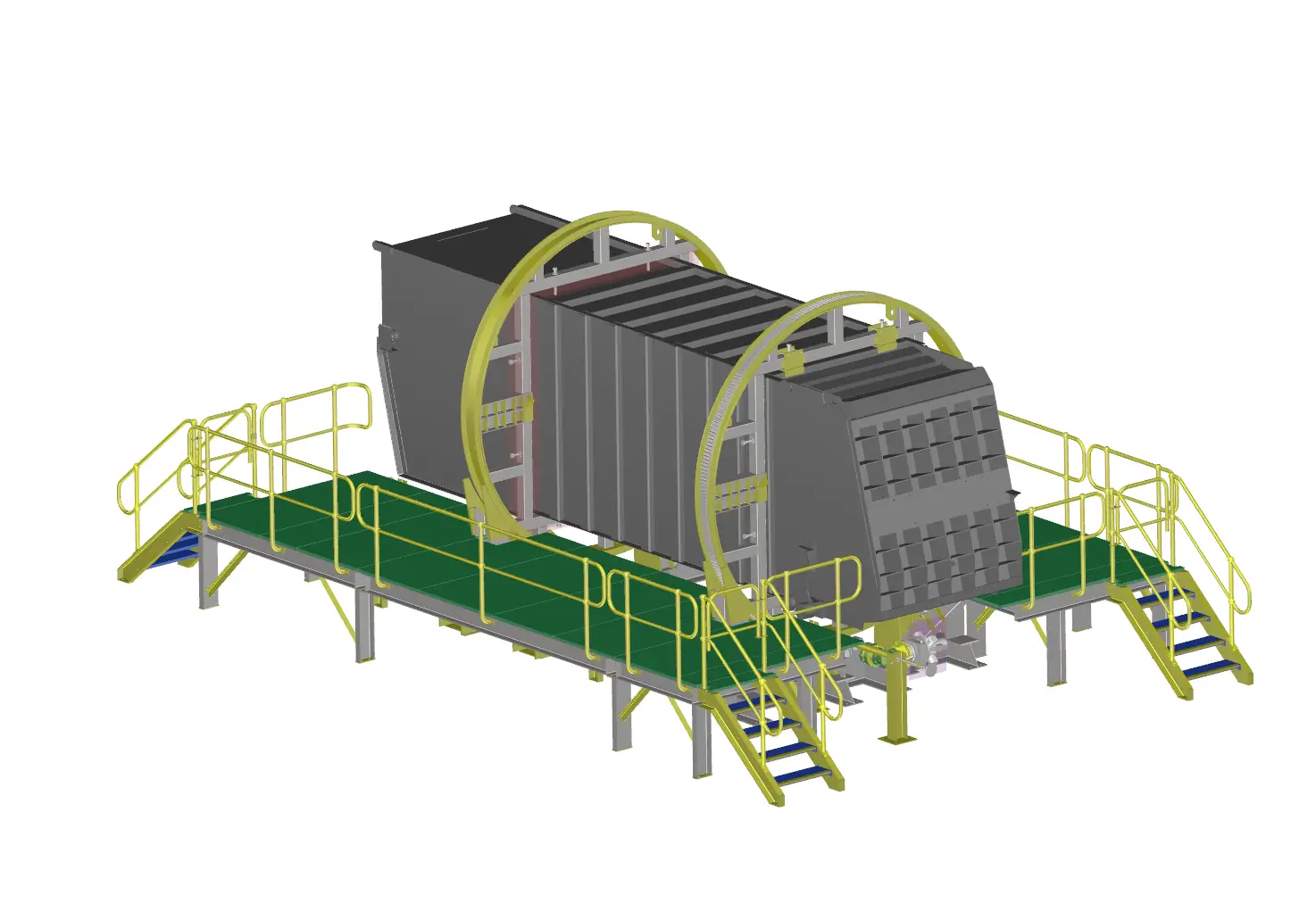

Tippler Refurbishment Feasibility

Glencore Port Operations in Townsville operate an export facility for minerals concentrate and refined copper within the Port of Townsville precinct. The concentrate in-loading rotaside tippler was identified as being at end of life and a feasibility study was commissioned to review a like-for-like replacement option for refurbishment of the tippler.

To facilitate feasibility-level costing, Orana Engineering was asked to provide electrical engineering and mechanical engineering assistance with provision of a concept design for the proposed refurbishment and upgrade.

By working closely with Glencore, and other consultants engaged on the project, Orana Engineering was able to contribute as part of a collective "owners engineering team" to the feasibility assessment of a significant engineering project in the Townsville Region.

TK102 Bypass Piping

When tasked with a major repair to one of their leaching tanks, personnel at Carpentaria Gold's Ravenswood Operations enlisted the assistance of Orana Engineering to develop a solution that would allow process operations to continue whilst leaching tank TK102 was out of service.

A site visit and discussions with the client suggested the installation of a bypass line around TK102. By utilising site information, Orana Engineering designerswere able to detail a new bypass line through the existing processing plant area. This involved minor modification of existing structural steel and addition of pipe supports for the new HDPE bypass pipeline.

Bypass piping was successfully installed during normal operation with only tie-ins needing to be installed during a single shut down.

Treated Water Boost Pumps

Oaky Creek Coal uses an onsite reverse osmosis plant to provide treated recycled water to various site operations. An opportunity was identified to use this recycled water for supply to critical equipment such as horizontal belt filters, thereby improving equipment water quality, reducing equipment downtime and lowering maintenance requirements.

Orana Engineering reviewed the performance of two existing boost pumps intended to provide high pressure treated water to a new horizontal belt filter. Hydraulic modelling was performed to predict future demand and thus determine the suitability of the existing pumps for use in the new application.

Orana Engineering also prepared a control philosophy for use by systems engineers to ensure safe operation of the pumps under all operating conditions.

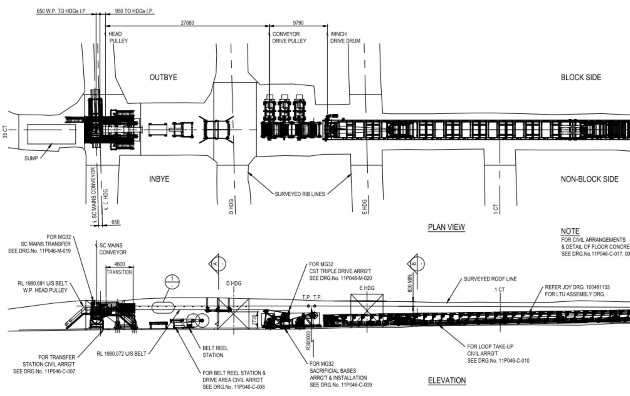

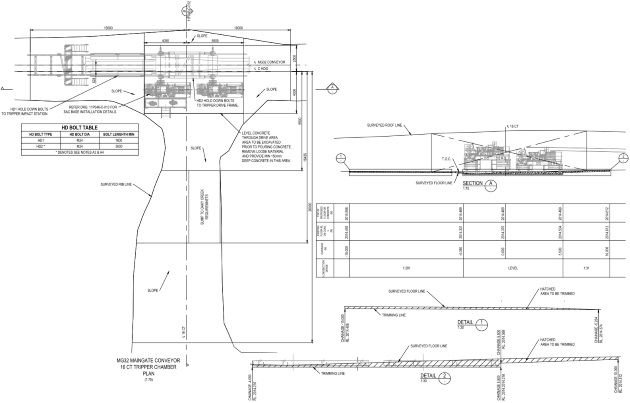

UG Conveyor Installations – MG32 Tripper Chamber

At Glencore’s Oaky No.1 underground coal mine, transportation of vast quantities of coal over long distances requires significant power. Often drive-head power is insufficient or constrained by allowable belt tension and an additional drive or power source is required to meet operating capacity. Additional power is commonly sourced from a driven conveyor tripper installed along the conveyor with appropriate excavation for the tripper.

Using the client’s existing mine plan to position the new tripper chamber, Orana Engineering design drafting personnel worked with site engineers to assess required chamber dimensions while simultaneously minimising the excavation of material.

Orana Engineering used AutoCAD to produce a drawing set detailing the mining required, and an overlay showing future equipment installations within the new chamber.

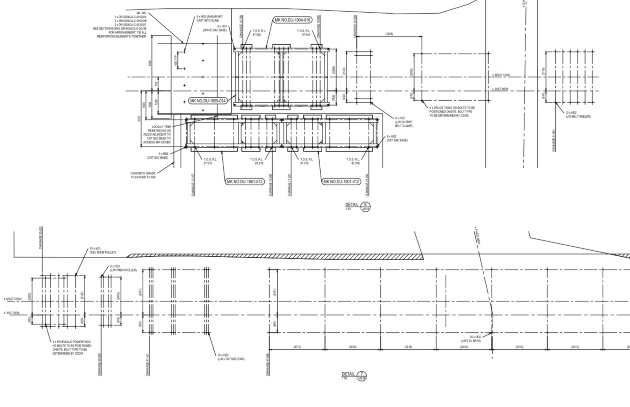

UG Conveyor Installations – MG32 Tripper Civil Design

Engineers at Glencore’s Oaky No. 1 underground coal mine engaged Orana Engineering to determine civil work requirements to install tripper equipment on the MG32 longwall conveyor. On completion of chamber mining, finished surfaces (rib and floor) may require modification for the installation of conveyor tripper equipment. The civil design must determine concrete grades for drainage, safe access and reinforcing for conveyor equipment, while minimising trimming and concrete required.

Manipulating “as-cut” survey data using AutoCAD, Orana Engineering design staff could accurately determine where tripper equipment could be installed with minimal trimming and concreting. A drawing set was produced detailing civil aspects of the tripper design, including chamber trimming, equipment mounting locations, configuration of reinforcing and relative concrete levels for drainage.

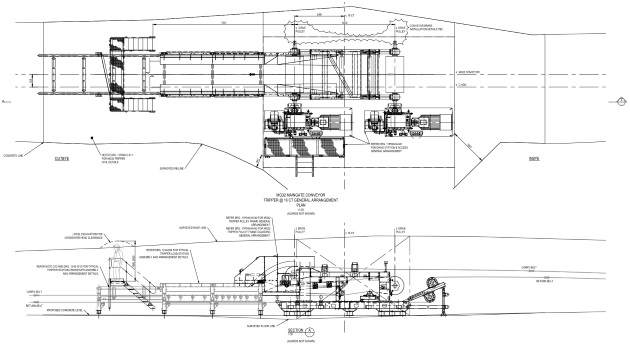

UG Conveyor Installations – MG32 Tripper Mechanical Design

Orana Engineering was engaged by Glencore to design and install a detailed arrangement of tripper drives, brakes, pulley frame and load station for the MG32 conveyor at its Oaky No.1 underground coal mine.

Mechanical design considerations included operating capabilities, unimpeded travel road access and minimum belt curves. The design was dependent on the civil installation previously detailed by Orana Engineering. Often equipment is simply re-located from previous installations with minor modifications. Orana Engineering has developed unique methods for completing this type of design efficiently and at reduced cost to our clients.

AutoCAD was used to develop a mechanical design, from which a drawing set was produced that detailed out the mechanical aspects of the tripper installation

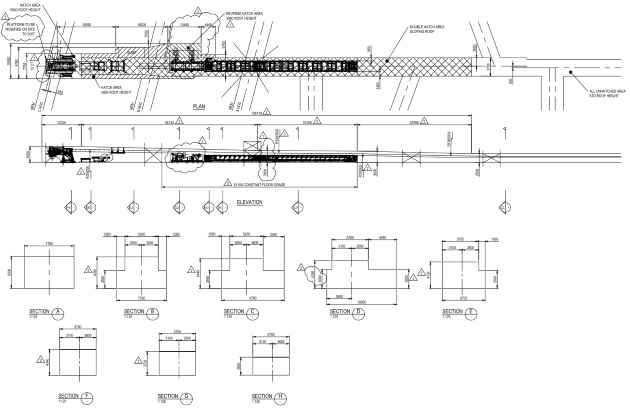

UG Conveyor Installations - MG Chamber Design

Mining millions of tonnes of material requires significant infrastructure and planning. Orana Engineering has been engaged on multiple occasions at Glencore’s Oaky No. 1 underground coal mine, to design new conveyor drivehead chambers to install equipment for longwall mining.

Using the client’s existing mine plan, Orana Engineering design drafting personnel worked in tandem with engineers to assess required chamber locations and dimensions, with consideration to the size and orientation of equipment to be installed and minimising the material to be excavated.

An AutoCAD drawing set was produced detailing the extent of mining required along with an overlay showing future equipment installations, enabling the client to efficiently complete chamber mining with a design suitable for future installations and minimal rework.

UG Conveyor Installations - MG Civil Installation

Engineers at Glencore’s Oaky No. 1 underground coal mine engaged Orana Engineering to determine civil work requirements to effectively utilise drive-head equipment in newly mined chambers for conveyor installations.

On completion of chamber mining, finished surfaces (rib and floor) may require modification for installation of the conveyor drive-head equipment. The civil design must determine concrete grades for drainage, safe access and reinforcing for conveyor equipment, while minimising trimming and concrete required.

Manipulating “as-cut” survey data using AutoCAD, Orana Engineering design staff could accurately determine where equipment might be installed with minimal trimming and concreting. A drawing set was produced detailing civil aspects of the conveyor design, including chamber trimming, equipment mounting locations, configuration of reinforcing and relative concrete levels.

Underground Workshop Concept Design

Due to expanding operations, Glencore's Oaky North underground operations saw benefit in having an underground workshop and refueling stations to reduce vehicle travel times and increase efficiencies. Orana Engineering was engaged to provide concept design and estimating assistance for project approval.

From communications with our client, Orana Engineering prepared concept general arrangement drawings for consideration. Based on these concept design drawings, a project capital estimate and project schedule were prepared for Oaky North.

From the information presented by Orana Engineering, the client could accurately consider whether the underground workshop was feasible and ensure that appropriate budgeting and project planning was completed at the concept design phase to improve confidence in the project prior to execution.

Wall Kit Drafting

BHP Billiton's Cannington Mine is a significant underground silver and lead mining operation in Western Queensland. Following completion of ore extraction from each stope, paste backfill is used to fill the open void and stabilise the area. This is achieved by constructing a fill wall which provides stability for areas being backfilled, eliminates intrusion, and allows a higher density of backfill.

Wall construction kits supplied to Cannington contained no documentation detailing the kit components. BHP Billiton engaged Orana Engineering to confirm the components in these kits.

Using measurements and sketches obtained from site, Orana Engineering design drafting personnel utilised AutoCAD to create a drawing set detailing the components required and fabrication details for each construction kit.