Engineering for Oil, Gas, Energy & Water

The oil and gas sector in Queensland has experienced rapid growth over past years with a number of basins throughout the region currently producing, or with the potential to produce oil and gas. The gas sector in particular is an area that benefits from the mechanical, electrical, structural and control systems engineering services that Orana Engineering can provide. We are experienced working with clients in the Surat and Bowen Basins, and are strategically placed to support future expansion into the Galilee Basin.

From the upstream operations of extracting, processing and compressing Coal Seam Gas (CSG) to the downstream process of converting the gas into Liquid Natural Gas (LNG) for shipment and export, our engineering services, which include design, project management, design drafting, revisions and drawing management, are intended to support the ancillary services of the oil and gas industry including fixed plant and infrastructure such as water treatment plants, compressors and power stations. Orana Engineering can also provide support for the ancillary services associated with Underground Coal Gasification (UCG) operations.

It is important that any contractor or supplier to the oil and gas industry is familiar with acts and legislation that govern the operations onsite, and Orana Engineering ensures that staff are conversant with these. For further information on the legislation, please follow the links below.

Petroleum and Gas (Production and Safety) Act 2004

Petroleum and Gas (General Provisions) Regulation 2017

Petroleum and Gas (Safety) Regulation 2018

Explore the case studies below to learn more about the value we can add for our oil and gas clients.

Orana Engineering Oil and Gas Engineering

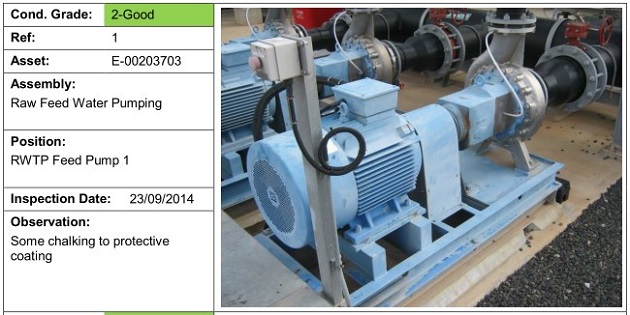

Plant Condition Assessment

Orana Engineering was requested by Veolia Water to perform a condition assessment of assets at the Kenya Water Treatment Facility which covered civil, structural, mechanical and electrical assets.

Inspections were completed over a period of 6 days with Orana Engineering personnel of various disciplines working with site representatives across all areas of relocatable plant infrastructure. Observations were recorded and photographed enabling a detailed register and report to be produced.

Orana Engineering updated the plant asset register to assist with ongoing management and to ensure observations were in a format practical for plant operators. The final report grouped items within categories to assist in prioritising actions and was used by the client to create an action plan for rectification of faults.

Building Certification

Monadelphous Group was contracted to deliver the Talinga Pipeline Compression Facility for Origin Energy’s APLNG project. Towards the end of plant construction, the Monadelphous team engaged Orana Engineering to complete structural inspections and provide Form 16 Building Certificates for structures ranging from small plant air shelters to entire compressor train buildings and associated platforms.

The inspections assessed construction to the requirements of AS4100: Steel Structures and AS1657: Fixed Platforms, Walkways, Stairways & Ladders - Design, Construction & Installation.

The work was completed within strict timeframes by employees from Orana Engineering’s Chinchilla Office, situated in close proximity to the site. This allowed multiple site visits to be conducted at very short notice and with minimal travel and mobilisation costs.

Combabula Bore Pump

Prime Pump Company was contracted by Origin Energy and Laing O’Rourke to supply an upgraded bore pumping system at Origin’s Combabula site. RIE Services was contracted by Prime Pump Company to supply and install electrical components for the upgrade, with Orana Engineering subsequently engaged by RIE Services to complete a fault protection study on the new installation.

Using SKM Power Tools for Windows software and manual calculation techniques for verification, together with information from RIE and Prime Pump Company, Orana Engineering produced an HV/LV model calculating fault levels and completing a protection co-ordination study.

From the study it was recommended a new circuit breaker be introduced to protect the transformer, variable speed drive and supply cables.

APA Group Tender

APA Group released a project for tender comprising electrical and instrumentation for rectification of hazardous area compliance issues. Condamine Electric Company (CEC) tendered on the work and engaged Orana Engineering to prepare a detailed estimate of costs to complete the rectification works.

Orana Engineering undertook a detailed review of the scope and drawings in the tender package to ascertain requirements. Quotes for non-standard equipment were obtained and a detailed cost estimate was created. Additionally, from the scope review Orana Engineering identified and compiled a comprehensive list of questions which were subsequently raised by CEC during a tender site visit. Upon provision of responses, Orana Engineering delivered a complete capital estimate to CEC for tendering.

QGC AIWT Design Review

Hutchinson Builders Toowoomba was contracted to deliver portions of the Water Aquifer Injection Trial at QGC’s Woleebee Creek site. Prior to construction, Hutchinson Builders engaged Orana Engineering to perform a design review of all mechanical technical documentation associated with the Pond Transfer Pump Station.

The review aimed to determine whether sufficient detailed information had been provided to allow Hutchinson Builders to successfully complete construction. Orana Engineering completed and issued a design review report which detailed recommendations from the review.

During construction, Hutchinson Builders also engaged Orana Engineering to perform an inspection of a buried HDPE pipeline and to assess the construction of the pipeline against requirements of engineering drawings and specifications.

Ash Water Return Pipeline Replacement

Ash slurry at CS Energy’s Kogan Creek Power Station is pumped to various locations around site via a pipeline originally installed for delivery of service water from the power station to the crusher area. With proposed pumping equipment capable of higher pressure output, a project was set up to review the engineering calculations and potential risks.

Orana Engineering was engaged to conduct concept design investigations considering options for repair or replacement of the pipeline. Outcomes from the review were provided to CS Energy summarising options considered and proposing the use of carbon steel (potentially lined for corrosion resistance) as the optimal replacement for fibreglass piping. Advantages and disadvantages of carbon steel were also presented such that the client was fully apprised of its properties.

As only limited drawings of the existing pipeline were available, Orana Engineering design drafters produced pipeline general arrangements for information.

Boiler Structural Brace

CS Energy’s Kogan Creek Power Station was experiencing intermittent lateral vibration in the structural bracing of two of its boilers. The assistance of Orana Engineering was sought in conducting a structural and vibrational engineering review of the affected plant to determine the source of the issue. The review included SpaceGASS modelling of the local structure surrounding the bracing to assess loading and determine member sizing. A modal vibration analysis was completed to determine the natural frequencies of the plant and structural bracing.

Following review, the option of installing cables for the bracing was discounted and it was recommended that new bracing for structural members be installed and connected to the midpoint on either side using a custom designed clamped fitting (to avoid welding to existing loaded brace) and installing a new cleat at the main structural member. The design solution increased the lowest natural frequency vibration mode shape for the structures and also reduced visible deflection.

Orana Engineering deliverables for the project included a Boiler Structural Beam Plan Arrangement and detail drawing ‘issued for construction’.

Brine Concentrator Drain Pump System

Orana Engineering was invited by MFE to provide an estimate for subcontract works for the Veolia Water brine concentrator drain pump system at Kenya Water Treatment Plant.

Brine concentrators at the plant periodically release high temperature and corrosive wastewater to floor sumps to control or monitor processes. The PVC pipework from floor sumps had become unserviceable due to the pipeline material not being rated for high temperatures. The existing drainage pipeline needed to be replaced with a durable system capable of withstanding high temperature corrosive wastewater.

Orana Engineering’s involvement in the project encompassed provision of engineering support (hydraulic, mechanical, civil and electrical design) and drafting support including revision of existing drawings and generation of new hydraulic, mechanical, civil and structural drawings with RPEQ supervision.

Brine Concentrator Engine Bay Crane

Veolia’s Kenya Water Treatment Plant contacted Orana Engineering for assistance with engineering design and drafting of a manual pull-along crane utilising existing support beams and able to travel in both long and cross travel directions. It was proposed for the fabricated cranes to be installed in each of the treatment plant’s three brine concentrator engine bays.

A member of Orana Engineering’s mechanical engineering team attended site to inspect existing infrastructure, take measurements and gather information. Upon return to Orana Engineering’s Chinchilla office the site data was reviewed, structural engineering calculations performed and information provided to the drafting office for translation to general arrangement and detailed design drawings suitable for fabrication purposes.

Brine Concentrator Stair Tower Rescue Lift Points

Veolia Water’s Kenya Water Treatment Plant contacted Orana Engineering to provide engineering and design drafting assistance in relation to installation of fall-arrest rescue anchor points to the brine concentrator stair tower.

Orana Engineering mechanical personnel undertook a review of applicable codes and standards in order to identify key safety considerations in the use of fall arrest systems. Calculations were performed on existing structural members locally to determine beam capacity for the addition of lugs at 6 points as identified by the client.

Deliverables for the project included an RPEQ supervised design for manufacture and installation of the lugs, revision of existing client drawings to reflect design changes and creation of a new drawing including both general and detailed information for new lug locations.

.jpg)

Fire Hydrant Extension

Personnel at Origin Energy’s Darling Downs Power Station contacted Orana Engineering seeking assistance in reviewing regulatory requirements of fire protection systems (detection, alarms, hydrants, emergency exits) relevant to areas of the site not fully protected by existing systems due to distance or obstruction.

Orana Engineering’s design was required to tie into the existing potable water fire line to supply a new fire hydrant / hose reel, while meeting operational fire-fighting requirements compliant with Australian Standards

Orana Engineering completed mechanical engineering, calculations and hydraulic modelling for review by a third party Fire Systems Designer and verification by an RPEQ Fire Engineer. Orana Engineering also undertook pipework design and drafting with RPEQ sign-off.

Deliverables to the client comprised a scope of work document, a testing / commissioning plan, budget estimate cost proposal for installation and building certification, and provision of a drawing set for the fire water extension.

.jpg)

GCB Enclosure

Origin Energy sought assistance from Orana Engineering in providing a concept design for shade shelters to be retro-fitted to existing GCB enclosures at its Uranquinty Power Station in southern New South Wales. The objective of the shelters was to reduce rainwater contact with GCBs and the design to be such that shelters could be lifted off for periodic maintenance of GCBs.

A third party undertook 3D scanning of the existing cover structures and provided resultant scan data for 3D modelling by our design team. SpaceGASS modelling of the structures and analysis of compliance to Australian Standards was also conducted prior to provision of the new enclosure concept to Origin Energy for review. Upon receipt of design approval, Orana Engineering developed and issued a scope of work for supply and installation of the GCB enclosure shelters.

.jpg)

HA Reclassification

Origin Energy’s Mount Stuart Power Station operated three power turbines driven by aviation kerosene and consideration was being given to converting these to operate on an alternative fuel source. Orana Engineering was engaged to conduct a hazardous area classification assessment covering re-classification of site areas relevant to the fuel conversion and to address handling of flammable gases produced as part of normal plant operation.

The objective was to establish whether an explosive atmosphere would exist around equipment following the proposed fuel conversion and to verify the classification and extent of hazardous areas in line with regulatory guidelines and standards AS 60079 Series and IE Model Code of Safe Practice, Part 15.

Upon conclusion of Orana Engineering’s assessment, the client was provided with a comprehensive Hazardous Area (HA) Classification Report confirming that ventilation at the plant was deemed adequate due to the outdoor location of most equipment and artificial ventilation within turbine and pump enclosures. Revised HA area classification drawings were also provided by Orana Engineering drafting personnel.

.jpg)

Oily Water Pond

Origin Energy’s Talinga Gas Plant oily water system treats water created during the gas compression process. Effluent from the system is pumped into the water-gathering network, delivering water to the main water treatment plant.

Orana Engineering was engaged by Origin Energy to evaluate the oily water system and conducted a high level assessment of options to reduce the risk of uncontrolled release of contaminated water from the wetlands system that was controlled by interim means.

Outcomes were presented to the client summarising options to reduce or eliminate identified risks. Orana Engineering subsequently provided detailed mechanical and electrical design and drafting for the approved option.

Deliverables for the project included a basis of design document, detailed design and a revison of the Wetland Operations & Maintenance Manual.

Orana 4 Pump Station

Veolia Water engaged Orana Engineering to look into options for a replacement pump station at its QGC Kenya Central Water Treatment Facility.

High level concept design investigations were initiated for options to replace the existing diesel driven manually controlled pump system for transferring brine from the site's Orana 4 Pond to the plant for treatment. Both a land based primed pump station and a water based floating pump station were given high level consideration. A detailed concept options report was developed for review and consideration by site stakeholders.

Sewage Treatment Plant Concrete Slab

CS Energy engaged Orana Engineering to provide engineering and drafting support in documenting the scope for onsite civil, electrical (earthing) and mechanical (shade sail and drain piping) supply and installation at its Kogan Creek Power Stations Sewage Treatment Plant.

The basis of design was provision of detailed design engineering of a bunded concrete slab to house two 22kL aerated tanks and a 20 foot container. The slab design was to include an effluent drainage system with a new discharge pipe to be connected to the existing underground wastewater drainage network. It was planned to remove existing tanks and pumps and the design scope prepared by Orana Engineering was to include details for filling and capping the residual drainage pipes and holes.

Design drawings generated by Orana Engineering personnel to support the scope of work included a general arrangement, a detailed drawing and a revised layout drawing.